Description

Nitinol Rod – Specifications

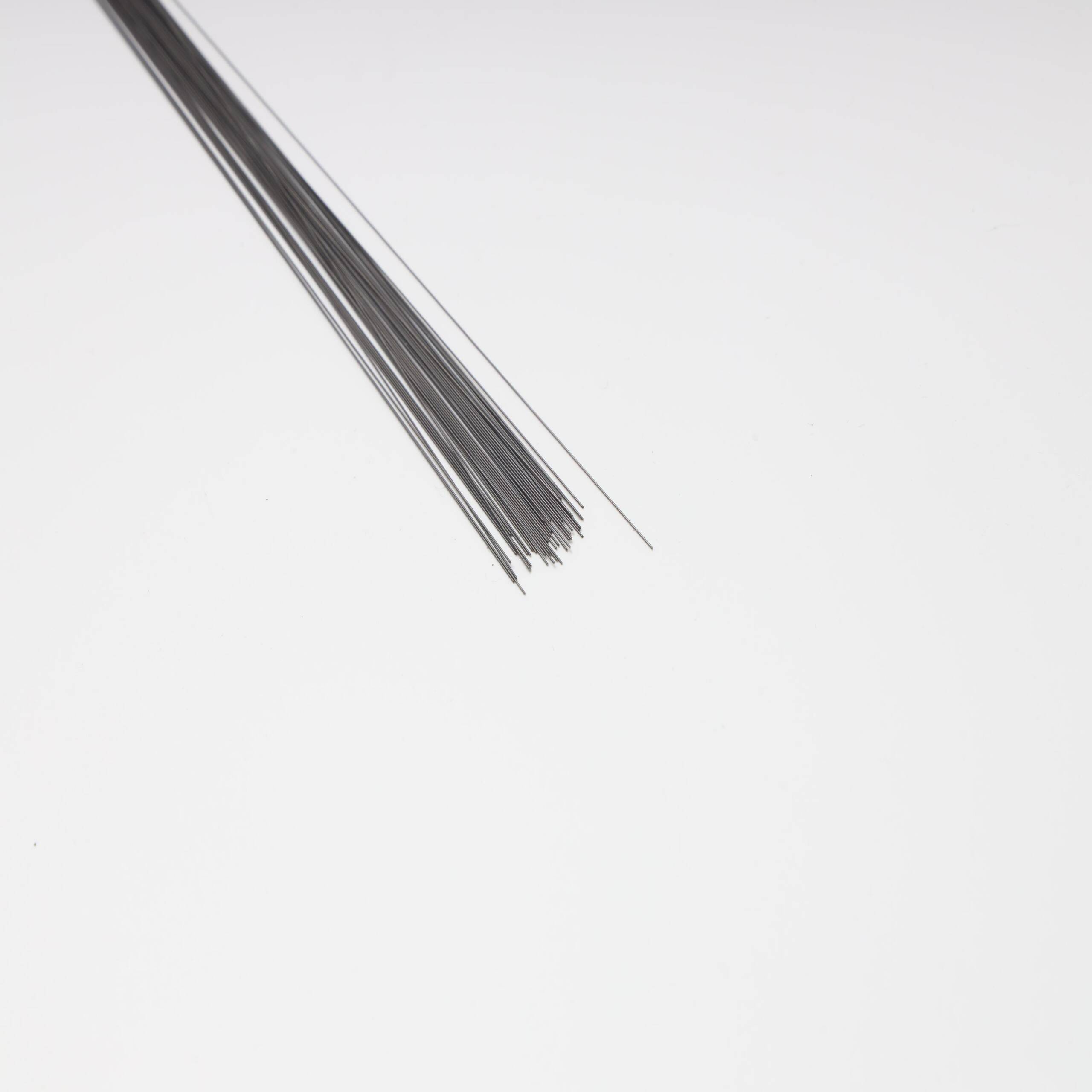

Product Name: Nitinol Rod

Specification: ASTM F2063-12

Af Temperature Range: -10°C to 120°C

Size: >0.2” Diameter

Surface Finish: Black, Pickled, Polished

Other Types Available: Bar, Rectangular Bar, and Customized Shapes

Related Product: NiTi Rod

Our Nitinol rod is precision-processed from high-quality nickel-titanium alloy, delivering consistent mechanical behavior and exceptional performance. When used for threaded fasteners, these rods are machined directly from solid Nitinol stock—a complex process due to the alloy’s shape memory behavior, high strength, and work-hardening tendencies.

While machining challenges do exist, our decades of expertise enable us to deliver custom Nitinol threaded rods that meet tight dimensional tolerances and unique application requirements. Whether you require precise threading, defined transition temperatures, or specialized surface finishes, we provide reliable solutions for high-performance demands in medical, aerospace, and industrial sectors.

Nitinol Rod Description

The Nitinol rod is an advanced engineering material fabricated from nickel-titanium alloy, celebrated for its unique thermo-mechanical behavior, including superelasticity and the shape memory effect.

Nitinol’s functionality stems from its temperature-dependent phase transformation, which enables deformation in its martensitic phase and complete shape recovery upon heating into the austenitic phase. This transformation offers reversible shape change with remarkable precision.

Notably, superelasticity occurs just above the material’s transformation temperature, where the rod can undergo large reversible strains—10 to 30 times more than typical metals—without heating.

All incoming Nitinol rods are inspected under strict quality protocols to ensure compliance with proprietary specifications, including chemical composition, ingot transformation temperature, microstructure, and material uniformity. Using single and multi-crystalline diamond die technology, we achieve an ultra-smooth and consistent surface finish.

We offer medical-grade Nitinol rods in both cold-worked (CW) and superelastic (SE) states. When properly heat-treated, SE Nitinol rods can withstand up to 8% recoverable strain at body temperature without permanent deformation.

Key Features of NiTi Rod

-

Complete martensite-to-austenite transformation range

-

Hysteresis reduction achievable via partial transformation or ternary alloying

-

Comparable machinability to 300-series stainless steel and titanium

-

Highly nonlinear response to temperature fluctuations

Applications of NiTi Rod

Thanks to its shape memory properties and superelastic response, Nitinol rod has become essential across mission-critical industries, including biomedical engineering, robotics, and high-performance actuators.

Medical Applications

-

Vascular Navigation: Kink-resistant guidewires for angioplasty catheter systems

-

Endoluminal Therapy: Self-expanding stents with ±0.1 mm dimensional control

-

Urology: Memory-based stone retrieval baskets for non-invasive lithotripsy

-

Orthodontics: Precision-controlled archwires (e.g., 0.017″ × 0.025″ profiles)

-

Device Fabrication: Form-retentive mandrels for PTFE extrusion tooling

-

Endoscopic Procedures: MRI-safe stylets with 360° steerability

Other Engineering Applications

-

Stress-Resistant Systems: Ideal for high load/unload plateau stress designs

-

High-Stiffness Needs: Cobalt-doped variants with enhanced tensile strength

-

Thermal Actuation: Used in temperature-responsive actuator systems

-

Cryogenic Environments: Maintains function in extremely cold settings

-

Cyclic Loading: Superior fatigue life at physiological temperatures (≈37°C)

FAQs About NiTi Rod

Q1. What is a Nitinol Rod?

A Nitinol rod is a high-performance material made from a nickel-titanium alloy known for shape memory and superelasticity. It is widely used in medical, aerospace, and industrial fields for its unmatched functional properties.

Q2. What are the Key Properties of Nitinol?

-

Thermally Activated Morphological Recall: Reverts to its original shape when heated to Af temperature

-

Superelasticity: Absorbs and recovers from large strain without permanent deformation

-

Corrosion Resistance: Highly resistant to oxidation and chemical degradation

-

Biocompatibility: Safe and effective for long-term implantation in the human body

Q3. Where is Nitinol Rod Commonly Used?

-

Medical Devices: Stents, orthodontic tools, guidewires, surgical instruments

-

Aerospace & Robotics: Actuators, temperature-sensitive mechanisms, adaptive components

-

Industrial Applications: Smart materials, responsive eyeglass frames, precision sensors

▸ Material Analysis: Complimentary DSC testing

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸Facebook account:(1) Facebook

Reviews

There are no reviews yet.