Description

Machining Nitinol – Precision EDM for Complex SE508 Components

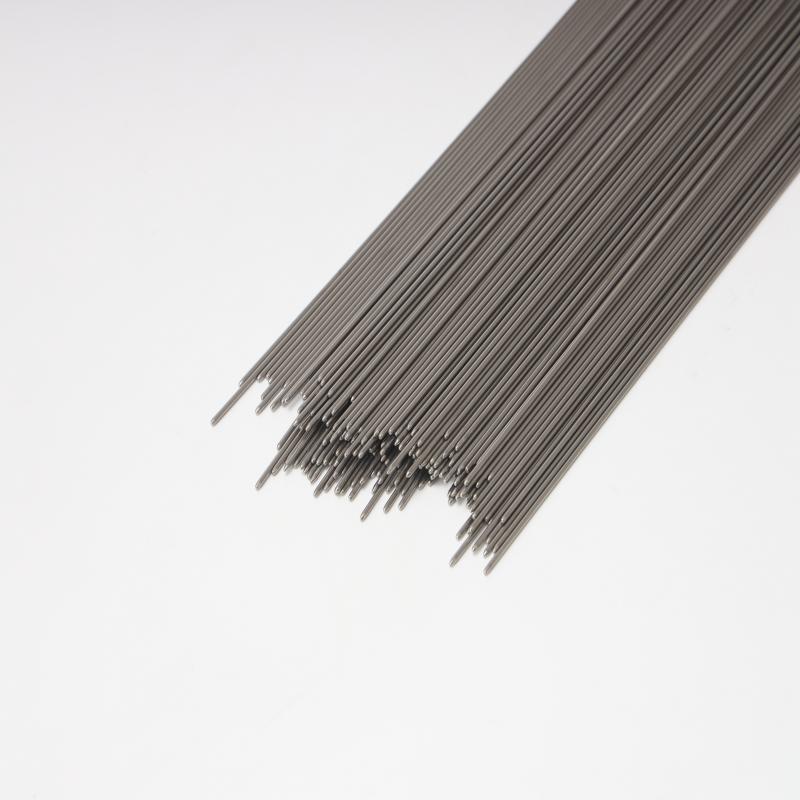

Expert Electrical Discharge Machining of Superelastic Nitinol

Machining Nitinol for High-Precision Performance

Machining Nitinol requires specialized technology and expertise. Our team delivers exceptional results using Electrical Discharge Machining (EDM) tailored for superelastic Nitinol SE508. This premium material meets ASTM F2063 standards and offers unmatched shape memory, flexibility, and biocompatibility—ideal for critical applications in medical, aerospace, and industrial fields.

EDM Capabilities for Machining Nitinol Wire and Rod

Our capabilities cover various Nitinol stock diameters:

-

Micro wires as thin as 0.1 mm (0.004 inches)

-

Standard diameters for typical device components

-

Robust rods up to 3.0 mm (0.118 inches)

Whether your design requires ultra-fine features or thick cross-sections, our machining nitinol process ensures accuracy and structural integrity.

Applications Requiring Precision Machining Nitinol

Our advanced EDM is ideal for producing precision-machined Nitinol parts across diverse sectors:

-

Medical Devices – Complex stents, heart valves, braces, and anchors

-

Surgical Tools – Flexible shafts, actuators, and surgical guides

-

Aerospace & Defense – Reliable actuator systems, rugged sensor enclosures, and high-strength couplings

-

Robotics & Automation – Gripper components, joints, and motion-transfer parts

-

MEMS & Microtechnology – Ultra-small sensors and actuators

-

Consumer Electronics – Precision mechanisms with flexible movement

-

Industrial Use – Resilient springs and Nitinol-based connectors

Why EDM Is Ideal for Machining Nitinol

-

No Contact, No Tool Wear – EDM eliminates physical stress, perfect for hard alloys

-

Minimal Heat Input – Preserves the shape memory and superelasticity of SE508

-

High Accuracy – Achieves tight tolerances, sharp corners, and burr-free edges

-

Supports Delicate Designs – Safely machines thin walls and intricate features

-

Custom Surface Finish – Tailored textures reduce or eliminate post-processing

-

Processes Hardened Nitinol – No need for post-machining heat treatment

-

Deep Nitinol Expertise – We optimize settings based on alloy behavior

-

From One-Offs to Production – Flexible service from prototype to volume runs

Machining Nitinol Has Never Been Easier

Skip the complexity. With our advanced machining Nitinol services using EDM, you get superior quality, preserved material properties, and design freedom. Partner with us for parts that meet your exact specifications—every time.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.