Description

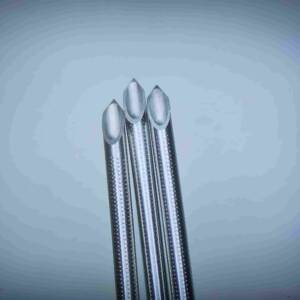

Black State Elastic Nitinol Wires for High-Performance Applications

Our Black State elastic Nitinol wires deliver exceptional superelastic performance, high strength, and long-term reliability. Featuring advanced shape memory properties and a distinctive black oxide surface, these wires provide superior fatigue resistance, corrosion protection, and dimensional stability. They are ideal for demanding medical, industrial, and engineering applications requiring precision and durability.

What Are Nitinol Wires?

Nitinol is a unique nickel-titanium alloy known for its superelasticity and shape memory effect. Black State elastic Nitinol wires undergo a specialized oxidation process that creates a stable black surface layer. This finish enhances wear resistance, corrosion protection, and surface consistency, while maintaining excellent mechanical performance. The result is a premium wire solution for critical applications.

Key Properties and Performance Advantages

Black State elastic Nitinol wires can sustain large reversible strains and instantly recover their original shape. This remarkable elasticity enables smooth, controlled motion and consistent force output. The material also offers outstanding fatigue life, high tensile strength, and excellent biocompatibility, making it especially suitable for long-term medical use. In addition, the black oxide surface improves durability, reduces glare, and enhances visual contrast during surgical procedures.

Precision Manufacturing and Material Composition

We maintain strict control over chemical composition to ensure stable transformation temperatures and predictable mechanical behavior. High-purity nickel and titanium are precisely balanced, while trace elements are tightly regulated. Our production complies with international quality standards, delivering consistent, repeatable performance across every batch.

Customization and Technical Support

We provide comprehensive customization services, including laser cutting, shape setting, EDM machining, precision grinding, and advanced joining techniques. Our engineering team works closely with you to transform complex concepts into reliable, high-performance components.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

Recommended Products

Reviews

There are no reviews yet.