Description

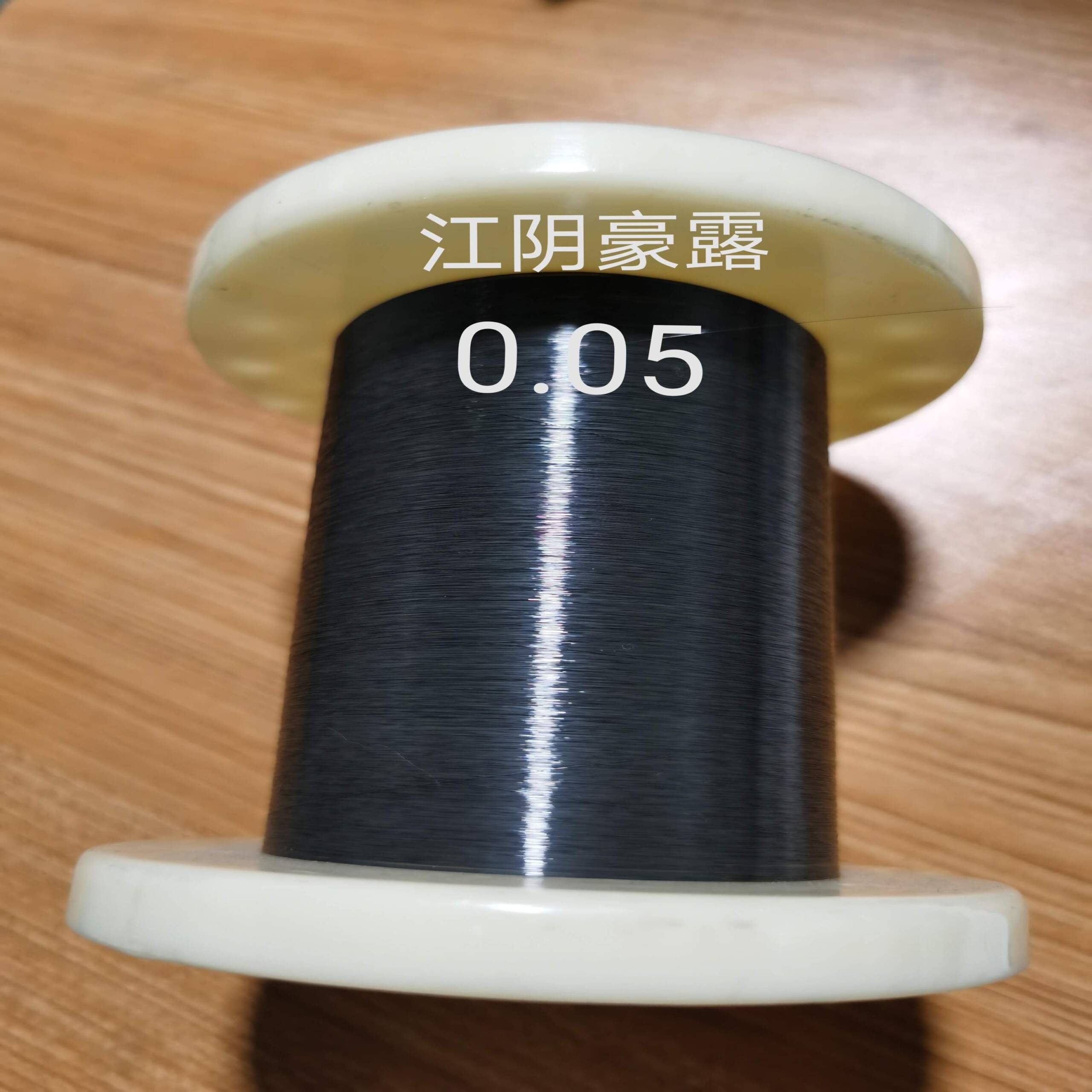

0.05 mm Black Oxidized Nitinol Wire for Industrial Alloy Applications

Materials for Industrial Alloy Applications

Our 0.05 mm wire is made from genuine Nickel-Titanium (Nitinol) alloy—celebrated for its Shape Memory and Superelasticity. Nitinol’s unique ability to remember its original form and resist deformation under stress makes it ideal for the most demanding industrial alloy applications. You’ll benefit from consistent mechanical performance and reliable resilience, even in micro-scale designs.

Precision Dimensions (Diameter Range)

We specialize in ultra-fine precision. This Nitinol wire measures exactly 0.05 mm (50 µm) in diameter, catering to industries that require the utmost miniaturization. Throughout our tightly controlled production process, every meter of wire undergoes rigorous diameter inspection to ensure ±0.002 mm tolerance. The result is uniform, ultra-thin wire that delivers repeatable dimensional accuracy—critical for any advanced industrial alloy application.

Surface Finish for Harsh Environments

To maximize durability and corrosion resistance in industrial alloy applications, we apply a controlled Black Oxide finish. This uniform, matte-black surface layer enhances wear protection in harsh operating conditions. The black oxide layer not only protects against corrosion but also improves compatibility with biological environments, ideal for certain medical applications.Whether you’re handling thousands of wire bends or integrating into corrosive environments, the finish guarantees smooth processing and long-term reliability.

Key Benefits for Industrial Alloy Applications

-

Shape Memory & Superelasticity: Harness Nitinol’s ability to undergo extensive deformation and return to its original shape—ideal for micro-spring and actuator elements.

-

Unmatched Miniaturization: At 0.05 mm diameter, this wire empowers designers to push the boundaries of micro-engineering in industrial alloy applications.

-

Enhanced Corrosion Resistance: The Black Oxide coating extends service life, even in aggressive chemical or humid environments.

-

Exceptional Fatigue Resistance: Nitinol’s inherent fatigue life minimizes failure risk in high-cycle industrial alloy uses.

-

Biocompatible Surface: For hybrid medical-industrial systems (e.g., implantable sensors), the oxide finish improves tissue compatibility.

-

Process-Ready: The uniform surface finish ensures excellent handling, bonding, and coating adhesion—streamlining your manufacturing workflow.

Targeted Applications

-

Medical Device Components

-

Ultra-fine guidewires, micro-catheter reinforcement, and minuscule stents.

-

Micro-actuators inside implantable devices, benefiting from Superelasticity to navigate narrow anatomical pathways.

-

-

Micro-Electro-Mechanical Systems (MEMS)

-

Micro-springs, micro-actuators, and flexible electrical contacts.

-

Precision industrial alloy applications in sensors and micromechanical switches, where reliable performance at microscopic scales is paramount.

-

-

Precision Instrumentation

-

Precision springs used in analytical instruments, miniature switches, and vibration-damping components in optical systems.

-

Fine actuation arms in laboratory instruments that require consistent force profiles.

-

-

Electronics & Connectivity

-

Micro-connectors and test probe pins engineered for high-cycle durability.

-

Flexible circuit elements and miniature antenna components demanding stable electrical conductivity in industrial alloy applications.

-

-

Robotics & Micro-Actuation

-

Small-scale gripping tools, soft actuator components, and motion control units in robotic automation.

-

Adaptive structures requiring repeatable movement within tight tolerances.

-

-

Aerospace & Defense Micro-Systems

-

Sensors in confined spaces, micro-valves, and vibration dampers for satellite subsystems.

-

Lightweight actuation mechanisms where reliability and size are equally critical.

-

-

Research & Development

-

Rapid prototyping of next-generation micro-devices and smart material systems.

-

Experimental applications in robotics, biomedical engineering, and aerospace testing.

-

-

Fluid Control Systems

-

Micro-valves, fine-metering devices, and precision regulators for gas or liquid flow.

-

Leveraging Nitinol’s actuation capabilities to modulate flow rates with extreme accuracy.

-

-

Consumer Electronics Micro-Components

-

Micro-camera mechanisms, tiny hinges, and micro-switches in wearables or handheld devices.

-

Components that must endure repeated cycle life while occupying minimal real estate on a printed circuit board.

-

Why Choose Our 0.05 mm Black Oxidized Nitinol Wire?

-

Unmatched Precision: Exact 0.05 mm diameter empowers groundbreaking miniaturization in industrial alloy applications.

-

Superior Performance: Utilize Nitinol’s Shape Memory and Superelasticity to solve complex design challenges.

-

Enhanced Durability: Black Oxide finish delivers outstanding corrosion resistance and wear protection, extending service life in demanding environments.

-

Proven Reliability: Consistent material properties and tight dimensional tolerances ensure stable performance in high-volume production.

-

Design Flexibility: Thin diameter and superelastic behavior allow intricate shaping and integration that traditional metals cannot achieve.

-

Reduced Failure Risk: Excellent fatigue resistance minimizes maintenance and downtime costs in mission-critical systems.

-

Improved Biocompatibility: Optimized for medical or bio-integrated industrial alloy applications, thanks to the oxide layer.

-

Seamless Manufacturing Integration: Uniform surface finish ensures trouble-free handling, coating adhesion, and downstream processing.

Elevate your next micro-engineering breakthrough. Our 0.05 mm Black Oxidized Nitinol Wire is purpose-built for precision industrial alloy applications where size, strength, and reliability converge. Choose this advanced Nitinol solution to drive innovation in your most demanding projects—and experience the future of industrial alloy performance today.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.