Description

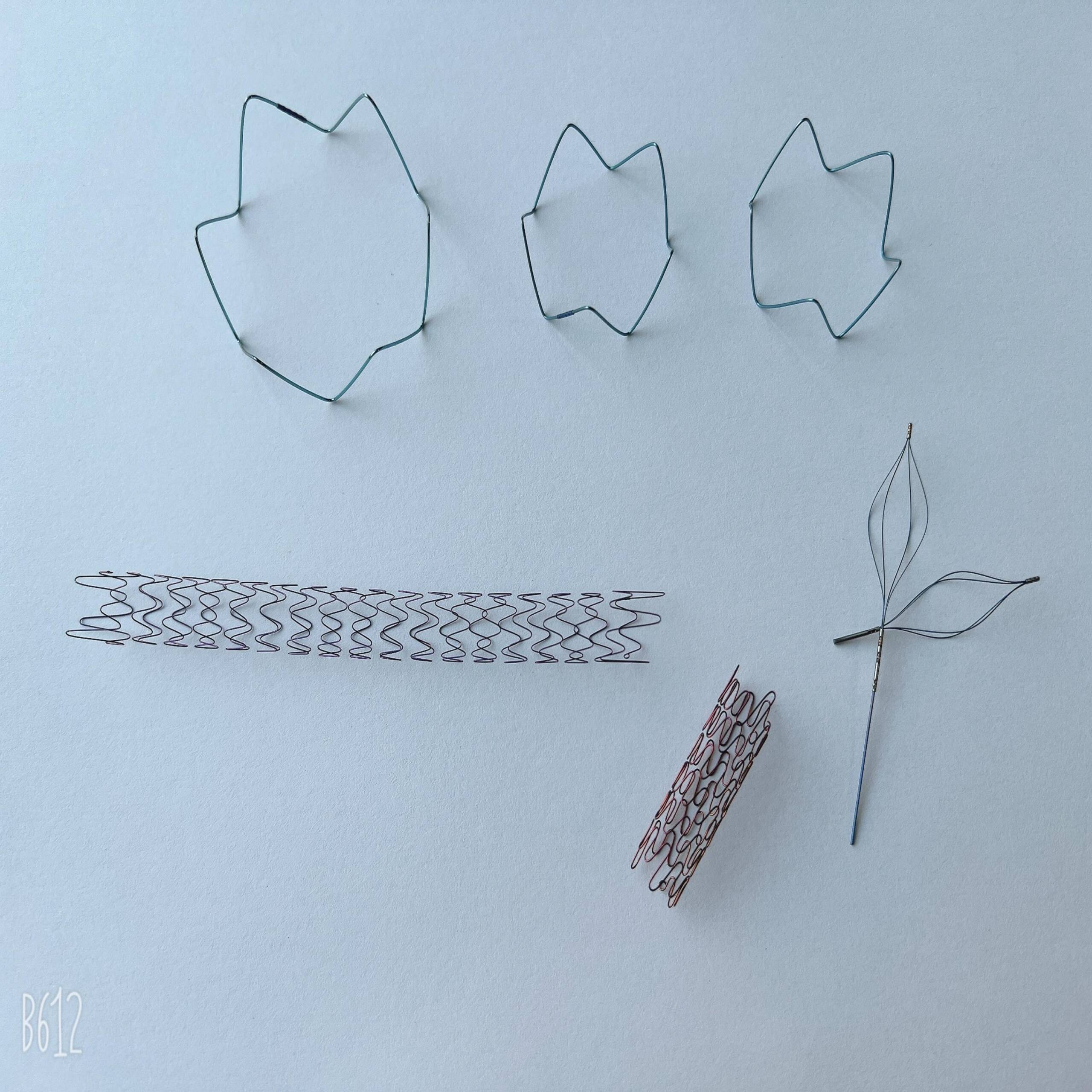

Precision Superelastic Nitinol Laser Cutting

Welcome to your trusted global source for superelastic Nitinol laser cutting. Based in Singapore, we specialize in producing precision components from this remarkable shape memory alloy. Our advanced facilities enable us to deliver complex geometries with unmatched accuracy to medical, aerospace, electronics, and research industries worldwide. From rapid prototypes to large-scale production, we support your innovations every step of the way.

Premium Superelastic Nitinol Materials

We use only top-grade superelastic Nitinol that bends, flexes, and returns to its original form repeatedly without fatigue. Its unique properties—exceptional fatigue resistance, corrosion resistance, and consistent behavior across temperature extremes—make it ideal for demanding applications where reliability is paramount.

Wide Diameter Range for Versatile Applications

Our laser cutting services support various superelastic Nitinol sizes:

-

Fine wires & tubes (0.1 mm – 2.0 mm): For minimally invasive medical devices, sensors, and fine mechanisms.

-

Medium profiles (2.1 mm – 10.0 mm): Used in orthodontic components, actuators, and dental tools.

-

Large formats (10.1 mm – 25.0 mm): Ideal for robust industrial springs, valves, and structural components.

We tailor to your specific dimensional needs—no matter the complexity.

Applications Across Innovation Sectors

Medical Devices

-

Stents, archwires, biopsy tools, catheter guidewires

-

Bone anchors, heart valve frames, neurological implants

Industrial & Consumer

-

Aerospace couplings, electrical connectors, vibration dampeners

-

Durable springs, eyeglass frames, smartphone mechanisms

Research & Emerging Tech

-

Robotics prototypes, lab-on-a-chip parts, micro-actuators

-

Energy harvesting devices and future mobility systems

Our superelastic Nitinol laser cutting enables the next generation of innovation.

Why Choose Us for Superelastic Nitinol Laser Cutting?

-

Precision Cutting: Tight tolerances (±0.05 mm), complex shapes, and burr-free edges.

-

Material Integrity: We protect the Nitinol’s shape memory and superelasticity by minimizing heat impact during laser processing.

-

Fast Turnarounds: Rapid prototyping and scalable production—all from our Singapore facility.

-

Experienced Team: Deep knowledge of Nitinol behavior and expert DFM (design for manufacturability) support.

-

Quality Assured: ISO 13485 compliant for medical parts, ASTM F2063 material traceability, and rigorous inspection protocols.

-

Singapore Advantage: Stable business hub, world-class logistics, and English-speaking technical support.

Let’s Cut Smarter—Partner with Singapore’s Nitinol Experts

Do you need ultra-precise superelastic Nitinol components? We’re here to help you realize your next breakthrough with quality, speed, and technical excellence. Contact our Singapore-based team for fast quotes and expert consultation. Get your superelastic parts done right—every time.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.