Description

Nitinol Plate: Versatile Shape Memory Alloy for Medical, Aerospace & More

Introduction to Nitinol Plate

Nitinol plate, a high-performance nickel-titanium (NiTi) alloy, is transforming advanced engineering with its exceptional thermomechanical behavior. It is available in both superelastic and shape memory alloy (SMA) forms, empowering engineers to tailor properties precisely for demanding applications. Moreover, industry leaders like Edgetech Industries LLC provide extensive customization—adjusting alloy composition, transformation temperatures (Af range: -10°C to 110°C), surface finish, and mechanical attributes such as loading plateaus and tensile strength.

Key Properties of the Alloy

This material stands out due to its dual functionality: shape memory effect (SME) and superelasticity. With the SME, it can return to a preset shape upon heating above its transformation temperature after being deformed. Meanwhile, its superelastic behavior allows it to undergo extreme strain—up to 10–30 times that of conventional metals—and still recover its original form without added heat.

Additionally, the alloy offers excellent fatigue life exceeding 10⁷ cycles, superior corrosion resistance (outperforming stainless steel), and biocompatibility. As a result, it is ideal for applications requiring reliability under cyclic stress and harsh environments.

Manufacturing Advantages

In terms of fabrication, Nitinol plate is highly adaptable to advanced processing techniques. It supports high-precision methods such as laser cutting, EDM (electrical discharge machining), and photo etching. Thanks to its flat format, manufacturers can produce both complex micro-components and large-scale precision parts with excellent dimensional control.

Furthermore, HM offers plates starting from ≥0.2” in thickness, with surfaces finished through pickling or polishing. This variety ensures seamless integration into diverse product designs and engineering needs.

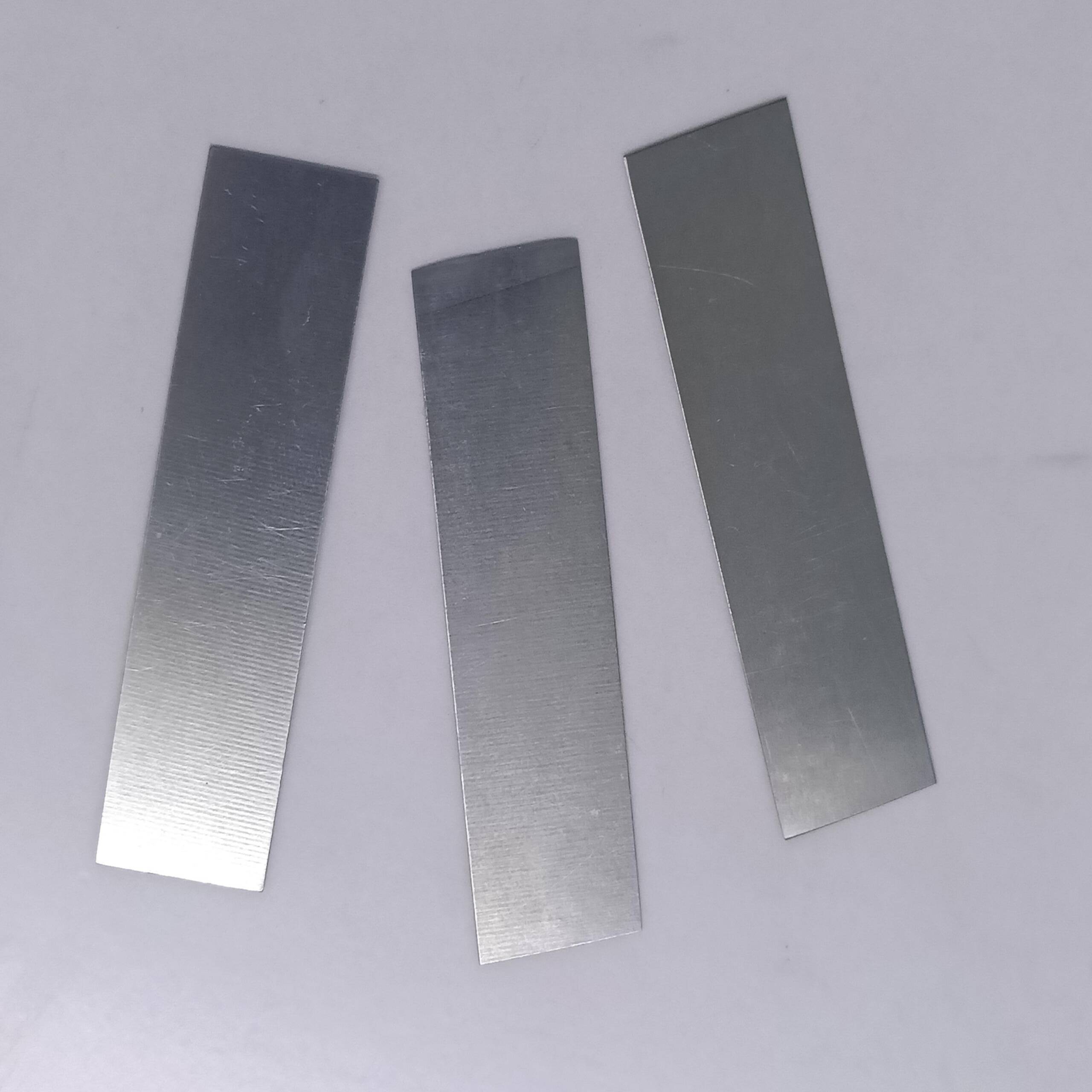

Surface Finish Options

Surface finish directly impacts performance and application suitability. To meet different requirements, this alloy is available in three finish types:

-

Black – Retains oxides and lubricants from processing; suited for industrial applications.

-

Cleaned – Chemically treated to remove surface residues; preferred for medical and cleanroom use.

-

Ground – Mechanically polished for high dimensional precision and smoothness.

Combined with customizable Af temperatures and electrical resistivity between 76–82 µΩ·cm, these surface options support its role in both functional components and sensing systems.

Industrial Applications

Due to its multifunctional properties, Nitinol plate is widely used in various advanced industries:

-

Medical: Bone plates, orthodontic archwires, and spinal fixation devices.

-

Aerospace: Lightweight structural brackets and vibration-damping systems.

-

Robotics: Artificial muscles, compliant mechanisms, and adaptive joints.

-

Consumer Electronics: Smart actuators, thermal triggers, and precision sensors.

Moreover, its high damping capacity and thermal responsiveness make it a key material in seismic protection systems and intelligent infrastructure.

Packaging and Delivery Assurance

To ensure product integrity during transit, each plate is securely packed in wooden crates or cushioned cartons. This protective packaging prevents shifting, abrasion, or impact damage—critical for components destined for high-performance environments.

Conclusion

In summary, Nitinol plate is redefining possibilities across modern industries. Its combination of shape memory behavior, superelasticity, corrosion resistance, and fatigue strength enables innovative engineering solutions that traditional metals simply cannot match. Whether in biomedical implants, aerospace systems, or next-generation robotics, this alloy continues to be a cornerstone of smart material design.

Reviews

There are no reviews yet.