Description

Product Overview

Our nitinol sleeve is a precision-engineered micro tubing component designed for demanding medical and industrial applications. Manufactured from advanced nickel-titanium alloy, this sleeve delivers outstanding flexibility, strength, and long-term reliability in extremely compact designs.

Thanks to its unique combination of superelasticity and shape memory, the nitinol sleeve solves complex design challenges where traditional metal tubes fail. It maintains dimensional stability while allowing repeated deformation, making it ideal for critical applications requiring both precision and durability.

Material Properties – Advanced Nitinol Alloy

This nitinol sleeve is produced using high-quality nickel-titanium alloy (Nitinol), known for two exceptional material characteristics:

-

Superelasticity: The sleeve can undergo significant bending and torsion, then instantly return to its original geometry without permanent deformation.

-

Shape Memory Effect: After deformation, controlled heating allows the sleeve to recover its pre-set shape with high accuracy.

In addition, the material offers excellent corrosion resistance, even in harsh biological environments. A stable titanium oxide surface layer enhances biocompatibility, making this nitinol sleeve suitable for long-term medical use.

Detailed Specifications

-

Inner Diameter: 0.0079 inches

-

Outer Diameter: 0.063 inches

-

Form: Precision micro sleeve / thin-wall tubing

-

Surface Quality: Smooth finish suitable for sensitive assemblies

Key Features of the Nitinol Sleeve

-

High radial strength in ultra-small dimensions

-

Excellent fatigue resistance under cyclic loading

-

Reliable dimensional consistency

-

Proven biocompatibility for medical applications

-

Stable performance in compact and high-motion environments

Primary Applications

The nitinol sleeve is widely used in advanced medical and engineering systems, including:

-

Catheter guide channels

-

Neurovascular and minimally invasive implants

-

Micro delivery and navigation systems

-

Aerospace precision mechanisms

-

Robotics and micro-engineering instruments

Medical device designers value the sleeve’s ability to safely navigate delicate anatomical pathways, while industrial engineers rely on its durability and corrosion resistance in confined spaces.

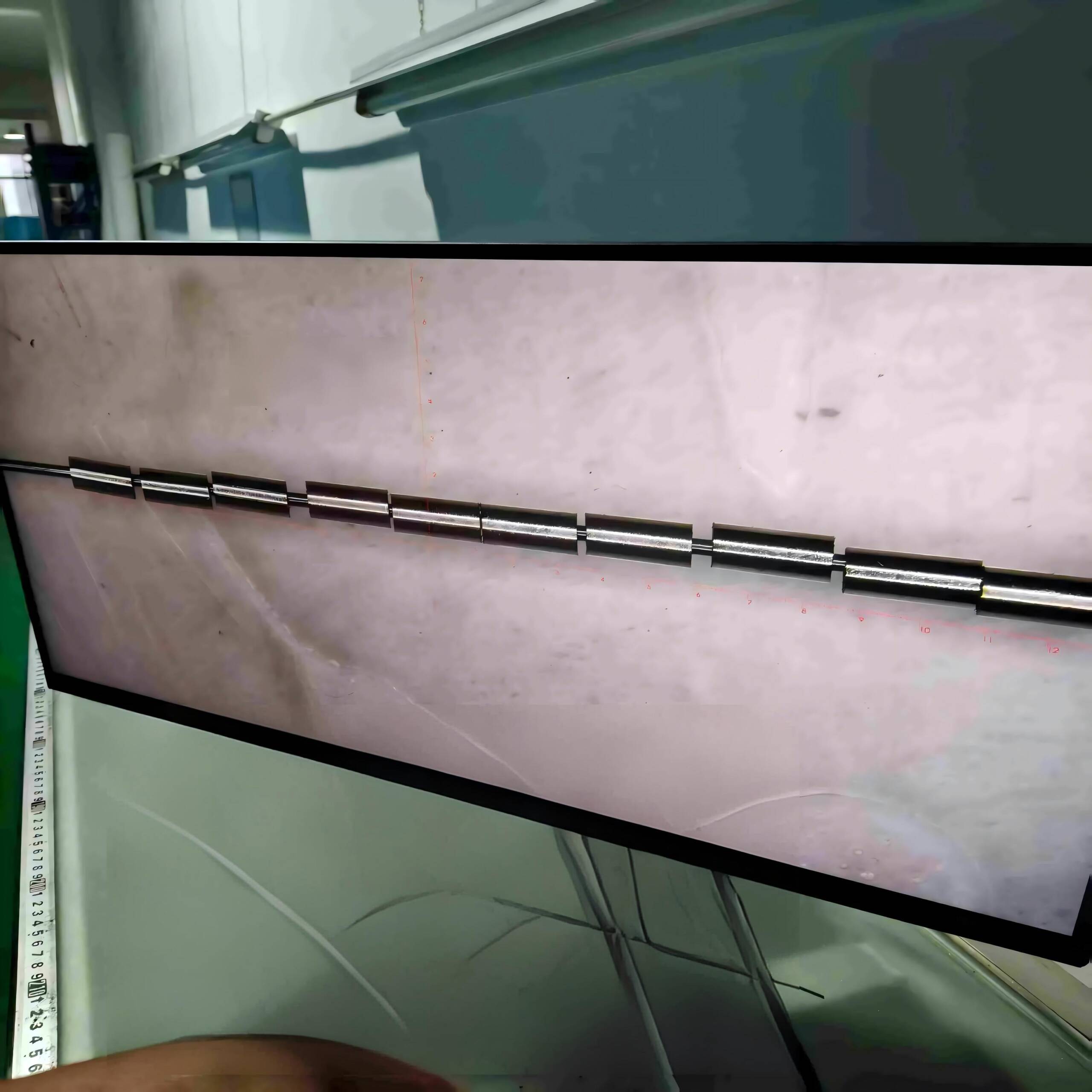

Manufacturing Capabilities & Quality Control

Our factory specializes exclusively in custom nitinol components. We convert raw Nitinol tubing into high-precision finished sleeves using:

-

Advanced laser cutting and micromachining

-

Precision heat treatment to activate superelastic properties

-

Electropolishing for ultra-smooth surface finishes

-

Medical-grade cleaning and packaging

Every nitinol sleeve undergoes 100% dimensional inspection, along with mechanical testing such as fatigue life and expansion force. This ensures consistent performance in your final assembly.

Customization is our strength. We support rapid prototyping, low-volume trials, and full-scale production based on your drawings and specifications.

MRI Compatibility of Nitinol Sleeves

Can a nitinol sleeve go in an MRI?

Yes. Nitinol is generally considered MRI-safe because it is not ferromagnetic. Most nitinol sleeves exhibit minimal magnetic attraction, heating, or movement during MRI scans.

However, factors such as cold working or final device configuration can influence MRI behavior. We recommend testing the completed device and following applicable MRI safety standards. Material certificates are available to support regulatory documentation.

Disadvantages of Nitinol – And How We Address Them

While Nitinol offers unmatched performance, it also presents challenges:

-

Higher material and processing costs

-

Difficult machining requiring specialized equipment

-

Sensitivity to heat treatment parameters

-

Potential fatigue concerns if improperly designed

Our expertise eliminates these risks. We optimize processing routes, control heat treatment precisely, and assist customers in designing components that fully leverage the benefits of nitinol sleeves while avoiding common pitfalls.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

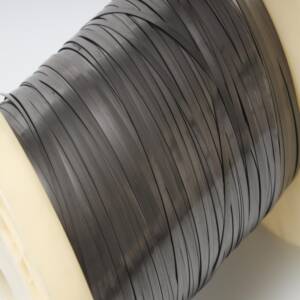

Nitinol Flat wire– Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube -engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.