Description

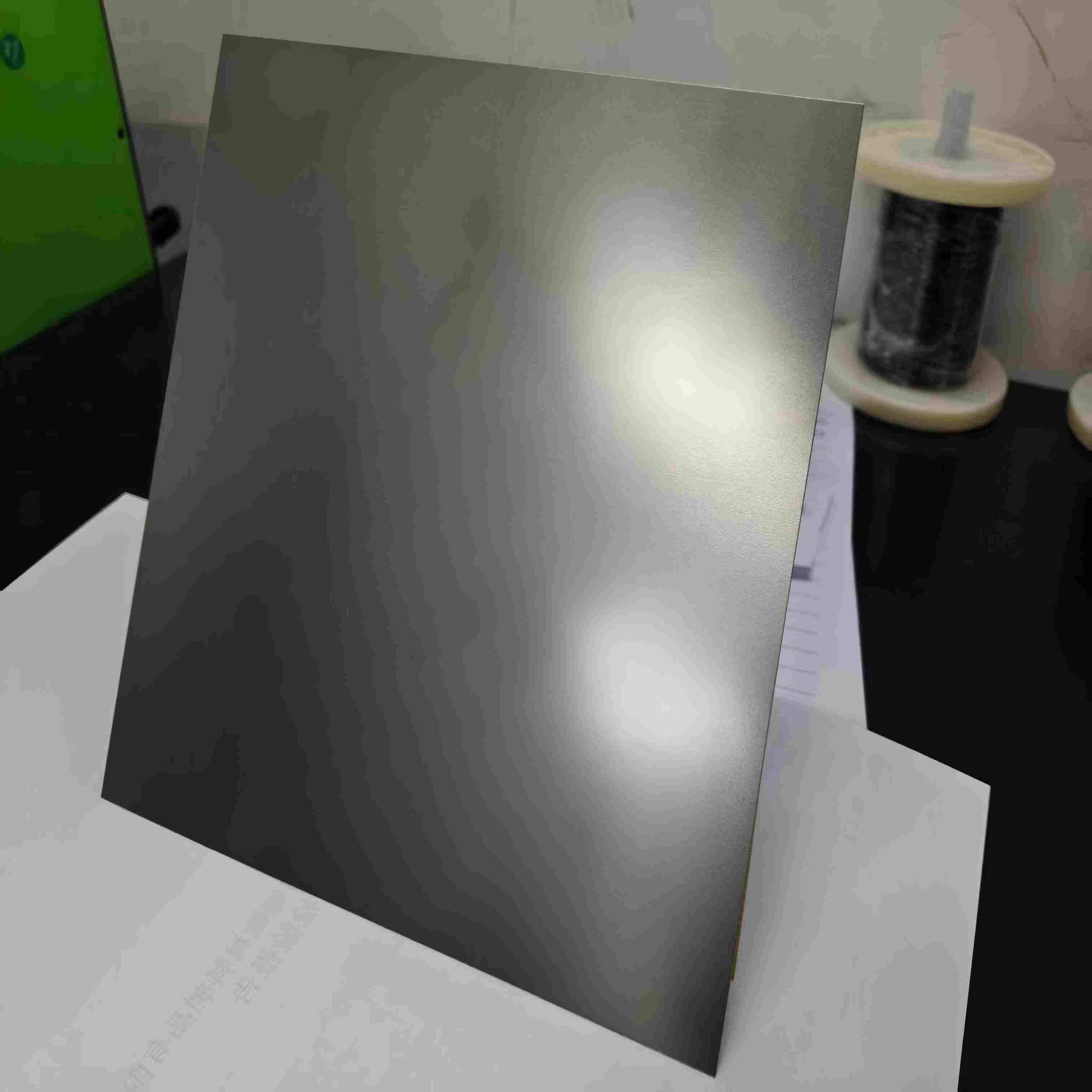

ASTM F2063 Nitinol Superelastic Sheet – All Sizes Available

Medical-Grade Superelastic Nickel Titanium Material

Our ASTM F2063 Nitinol sheet is manufactured from a true superelastic nickel-titanium alloy designed for demanding applications. This medical-grade material strictly complies with ASTM F2063, ensuring consistent chemistry, excellent mechanical performance, and outstanding reliability.

Unlike conventional metals, this superelastic Nitinol sheet can bend, flex, and recover repeatedly without permanent deformation. At room temperature, the material remains fully austenitic, delivering exceptional elasticity and fatigue resistance even under extreme strain.

Product Specifications – ASTM F2063 Nitinol Sheet

-

Product Name: Nitinol Superelastic Sheet

-

Material Standard: ASTM F2063

-

Condition: Superelastic / Austenitic at room temperature

-

Available Thickness: 0.05 mm – 3.0 mm

-

Available Width: Up to 300 mm

-

Standard Length: Custom cut according to your drawings

-

Surface Finish Options: Mill finish, polished finish, pickled finish

-

Transformation Temperature (Af): Below +15 °C (customizable upon request)

-

Certification: Full mill test report (MTR) and material certification provided

Performance Advantages of ASTM F2063 Nitinol Sheet

The defining feature of our nitinol sheet is its remarkable superelasticity. The material can withstand strains of up to 8% and fully return to its original shape, where traditional metals would permanently deform or fail.

In addition to flexibility, this nickel titanium sheet offers:

-

Excellent corrosion resistance

-

Long-term dimensional stability

-

Superior fatigue life

-

Proven biocompatibility for medical use

The sheet is supplied flat, uniform, and stress-controlled, making it ideal for laser cutting, stamping, chemical etching, and precision forming processes.

Typical Applications of Nitinol Superelastic Sheets

Thanks to its unique properties, Nitinol sheet is widely used across multiple industries:

-

Medical devices: orthopedic bone plates, implants, surgical instruments

-

Aerospace: deployable structures, adaptive components

-

Automotive: vibration-resistant and flexible components

-

Consumer electronics: compact, durable structural parts

Its ability to combine strength, flexibility, and recovery makes it a preferred solution for smart and adaptive designs.

Precision Manufacturing & Quality Control

We specialize in precision flat Nitinol products and manage the entire production chain in-house. Starting from certified raw materials, we use vacuum melting to achieve ultra-clean chemistry. The alloy is then hot forged, hot rolled, and precision cold rolled to exact thickness requirements.

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Reviews

There are no reviews yet.