Description

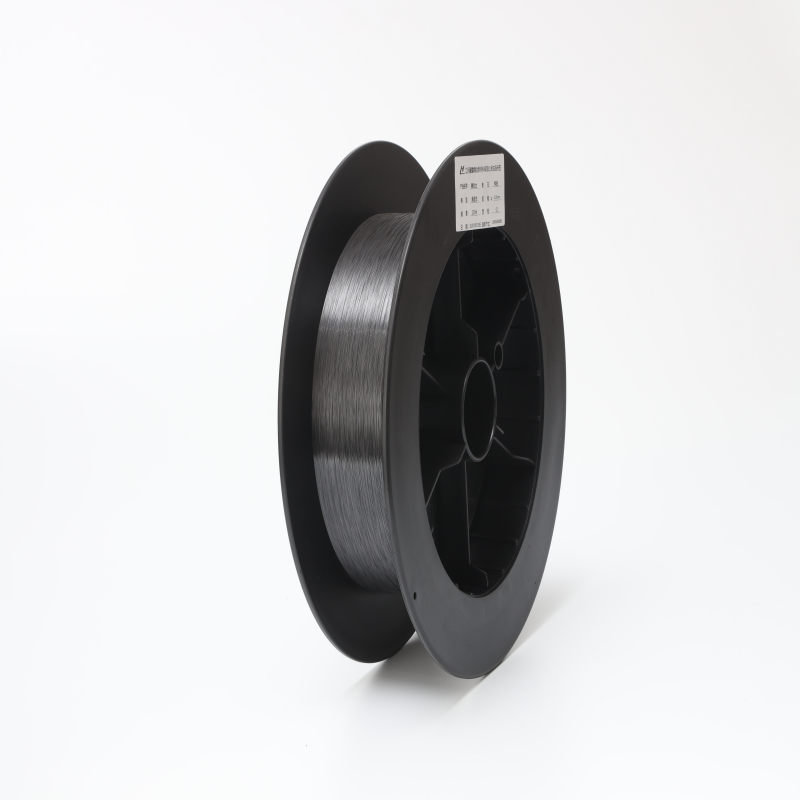

0.20mm Black Oxidized Nitinol Wire for Advanced Alloy Development

Unlock new possibilities in alloy development with our 0.20mm Black Oxidized Nitinol Wire. Designed for next-generation smart material applications, this wire integrates superior mechanical behavior with engineered surface properties. Whether you’re advancing medical technology, precision robotics, or miniaturized sensors, this product provides the ideal platform for cutting-edge innovation in alloy systems.

Engineered Materials for Alloy Development Excellence

High-Purity Core Composition

Our wire begins with a precise blend of high-purity Nickel and Titanium—essential for reliable transformation temperatures and mechanical responsiveness. This elemental balance supports consistent performance in demanding alloy development environments.

Advanced Thermal Processing

We apply controlled manufacturing techniques to ensure uniform shape memory and superelasticity throughout each length of wire. This guarantees optimal results in both experimental and production settings.

Integrated Black Oxide Surface

A specialized oxidation process forms a durable, adherent black oxide layer—not simply a coating but a functional enhancement that is critical in high-performance alloy engineering.

Optimized Surface Properties for Demanding Alloy Projects

Uniform Oxide Layer for Surface Integrity

Our process delivers a consistently blackened finish with excellent adherence and durability—ideal for applications involving friction, strain, or chemical exposure.

Reduced Friction and Enhanced Lubricity

This wire glides effortlessly through complex pathways, reducing resistance and minimizing abrasion. It’s ideal for use in catheter systems, actuators, and other dynamic systems developed during alloy innovation.

Corrosion and Wear Resistance

The black oxide layer resists degradation in harsh biological and industrial environments—preserving the functionality of the base alloy over time.

Biocompatible Surface for Medical Alloy Systems

Engineered for safe interaction with bodily tissues and fluids, the black oxide finish enhances safety and performance for implantable and interventional devices.

Precise Diameter Control for Alloy Development Applications

Ultra-Fine 0.20mm Diameter

This wire’s specific size enables delicate assembly and motion control, essential in many alloy development use cases including surgical tools and MEMS components.

Dimensional Accuracy & Consistency

Tight manufacturing tolerances ensure consistent diameter throughout every meter—critical for stress distribution and device performance.

Custom Diameters on Request

We can tailor sizes to match your alloy testing or R&D specifications upon request.

Innovative Applications Powered by Alloy Development

-

Medical Device Development

From guidewires to endoscopic tools, the kink resistance and flexibility of this wire make it ideal for next-generation minimally invasive devices. -

Micro-Actuators & Smart Mechanisms

Leverage the shape memory effect in robotic assemblies and MEMS components for compact, reliable motion solutions. -

Advanced Sensors

Its predictable stress-strain response is ideal for precision strain gauges and position feedback systems in smart devices. -

Orthodontic & Dental Technologies

Used in archwires that apply steady, biologically gentle forces—supporting controlled movement. -

Scientific Research in Alloy Systems

Enable breakthroughs in metallurgy, surface science, and biomedical engineering with a wire that supports experimental precision. -

Micro-Electronic Connectors

Supports flexible, fatigue-resistant electrical pathways for compact circuits and wearable tech.

Why This Wire Leads in Alloy Development Solutions

-

Superior Mechanical + Surface Synergy

Combines Nitinol’s superelasticity with the strength and low-friction properties of the black oxide layer. -

Enhanced Biocompatibility

Meets safety standards for use in contact with the human body—perfect for medical implants and instruments. -

Ultra-Smooth Handling

Delivers improved navigation through tortuous geometries and reduced insertion force during use. -

High Kink Resistance at Micro-Scale

Maintains flexibility and strength at a critical 0.20mm diameter—key in catheter design and micro-assemblies. -

Reliable, Batch-to-Batch Quality

Every production run is backed by rigorous quality checks to ensure consistent material behavior. -

Expertise in Alloy Processing

We understand not only how Nitinol behaves, but how to tailor it through surface engineering for advanced alloy development needs.

Drive Innovation with the Right Alloy Wire

This is more than just Nitinol wire—it’s a result of precision-focused alloy development. From lab-scale experiments to clinical applications, our black oxidized 0.20mm wire supports breakthroughs across industries. Let us help you build smarter, smaller, and stronger with this advanced material platform.

•Diameter & Tolerance

| Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) |

| 4.000-2.000 | ±0.025 | 0.350-0.260 | ±0.010 | 0.08-0.050 | ±0.005 |

| 2.000-1.000 | ±0.020 | 0.260-0.150 | ±0.007 | 0.050-0.025 | ±0.005 |

| 1.000-0.350 | ±0.010 | 0.150-0.080 | ±0.005 | 0.025-0.018 | ±0.003 |

•Mechanical properties

| Max force(N) | Tensile(MPa) | Elongation % | Upper stress(MPa) | Residual strain(WT%) | At temp |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 55.96 | (10±10) |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 56.1 | (-30±10) |

| Base on diam | ≥1000 (1350) | ≥10 (15) | ≥400 (460) | <0.5 50.0 | (60±10) |

▸ Expert Guidance: 24/7

▸ Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

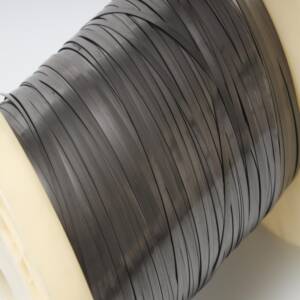

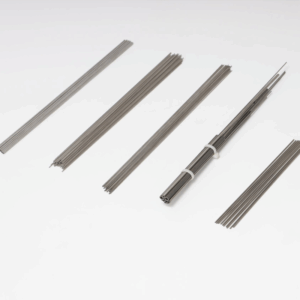

Nitinol Flat wire– Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.