Description

Unlock Next-Level Performance with Advanced Nitinol Manufacturing

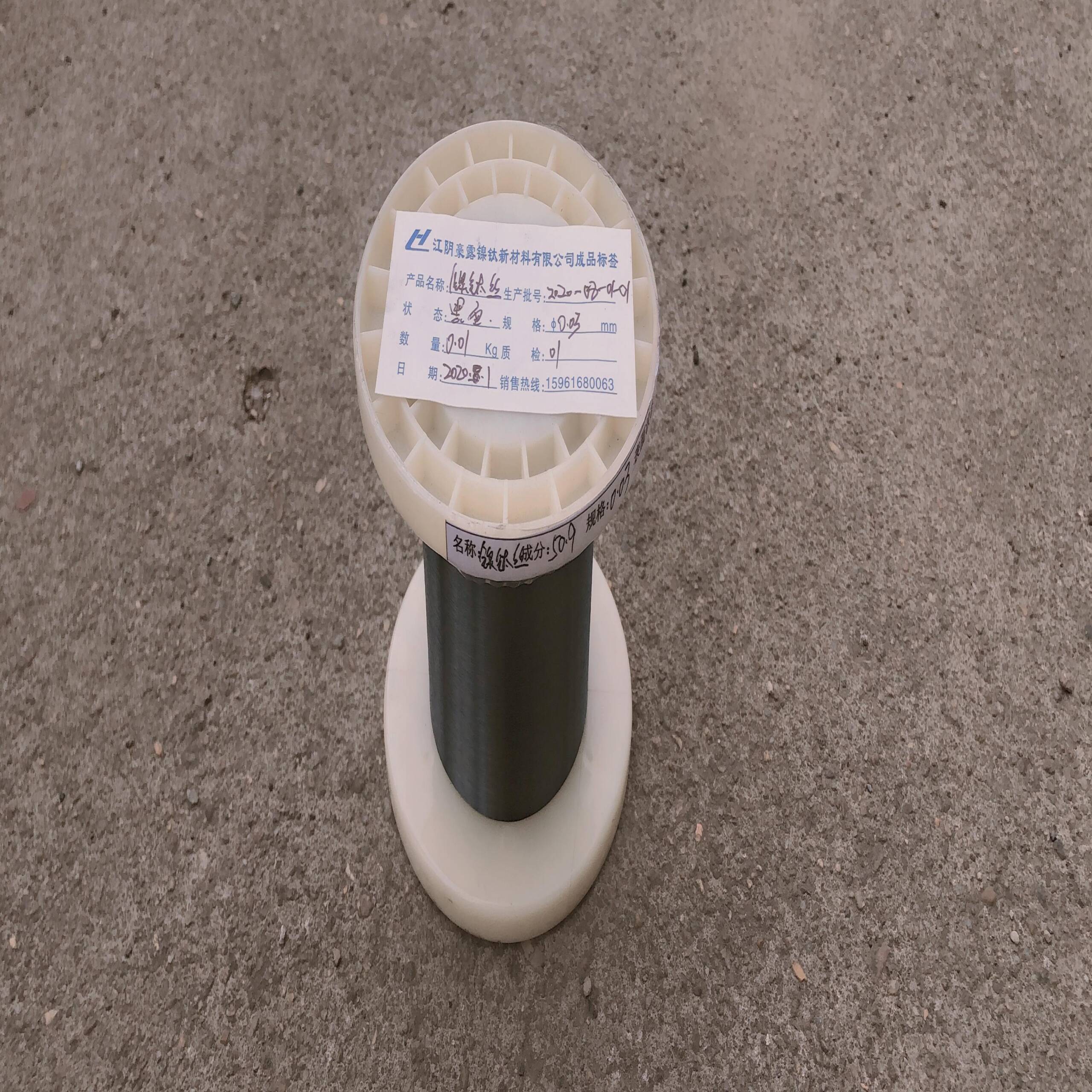

Engineered for cutting-edge innovation, our Black Oxidized Nickel Titanium (Nitinol) Wire, with a micro-scale 0.03mm diameter, is the result of expert nitinol manufacturing focused on precision, reliability, and medical-grade performance. Whether you’re designing the next-generation neurovascular device or a high-precision MEMS component, this wire offers unmatched functionality, flexibility, and consistency.

1. Engineered from Premium Nickel and Titanium Alloys

-

Manufactured with ultra-high purity nickel and titanium for optimal alloy integrity.

-

Consistent composition ensures robust superelasticity and reliable shape memory effect.

-

Our advanced nitinol manufacturing process delivers excellent material homogeneity.

-

Fully compliant with international biocompatibility standards such as ASTM F2063.

-

Exceptional corrosion resistance tailored for implantable and high-risk environments.

2. Enhanced Surface with Black Oxidized Finish

-

Specialized black oxide layer ensures uniform coverage and aesthetic distinction.

-

Surface finish significantly boosts corrosion resistance and biocompatibility.

-

Low-friction properties improve device delivery and surgical navigation.

-

Protective coating reduces damage during handling and assembly.

-

Offers a chemically stable, non-reactive interface for long-term implantation.

3. Ultra-Fine Precision Diameter: 0.03mm

-

We specialize in manufacturing ultra-fine 0.03mm nitinol wire with tight tolerance.

-

High precision enables predictable performance and reliable mechanical behavior.

-

Ideal for minimally invasive procedures, where flexibility and strength are vital.

-

Supports complex microstructures in MEMS, sensors, and miniature actuators.

4. Built for Critical Applications

-

Medical Guidewires: Navigate tiny vessels with superior trackability.

-

Micro-Catheters: Ensure precise therapy delivery in confined spaces.

-

Orthodontic Archwires: Achieve gentle, controlled tooth movement.

-

Vascular Stents & Filters: Integrate into life-saving micro-components.

-

Neurovascular Devices: Deliver safe, effective treatment for brain vessels.

-

Surgical Tools: Enable intricate maneuvers with nitinol-enhanced flexibility.

-

Ophthalmic Implants & Endoscopes: Provide reliability in sensitive applications.

-

Advanced MEMS & Robotics: Power high-performance micro-scale motion and sensing.

5. Why Choose Our Nitinol Manufacturing Expertise?

-

Industry-Leading Knowledge: We focus exclusively on advanced nitinol manufacturing.

-

Rigorous Quality Control: Every wire undergoes strict inspection and testing.

-

Consistent Results: Dependable properties across every production batch.

-

Optimized Mechanics: Benefit from tailored shape memory and elasticity curves.

-

Biocompatibility & Safety: Built for medical-grade reliability and longevity.

-

Durability Under Stress: Oxide finish protects from environmental degradation.

-

Friction-Reduced Performance: Improve procedural ease and device delivery.

-

Precision Engineering Support: Collaborate with our specialists for technical success.

Partner with a Trusted Nitinol Manufacturing Expert

Your application deserves wire engineered with absolute precision. Our 0.03mm black oxidized nitinol wire combines exacting dimensional control, robust biocompatibility, and cutting-edge nitinol manufacturing expertise. Designed for the most demanding micro-scale environments, it’s the material of choice for advancing medical technology and ultra-compact devices.

Contact us today to discuss your performance needs and benefit from a reliable, innovation-driven nitinol partner.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.