Description

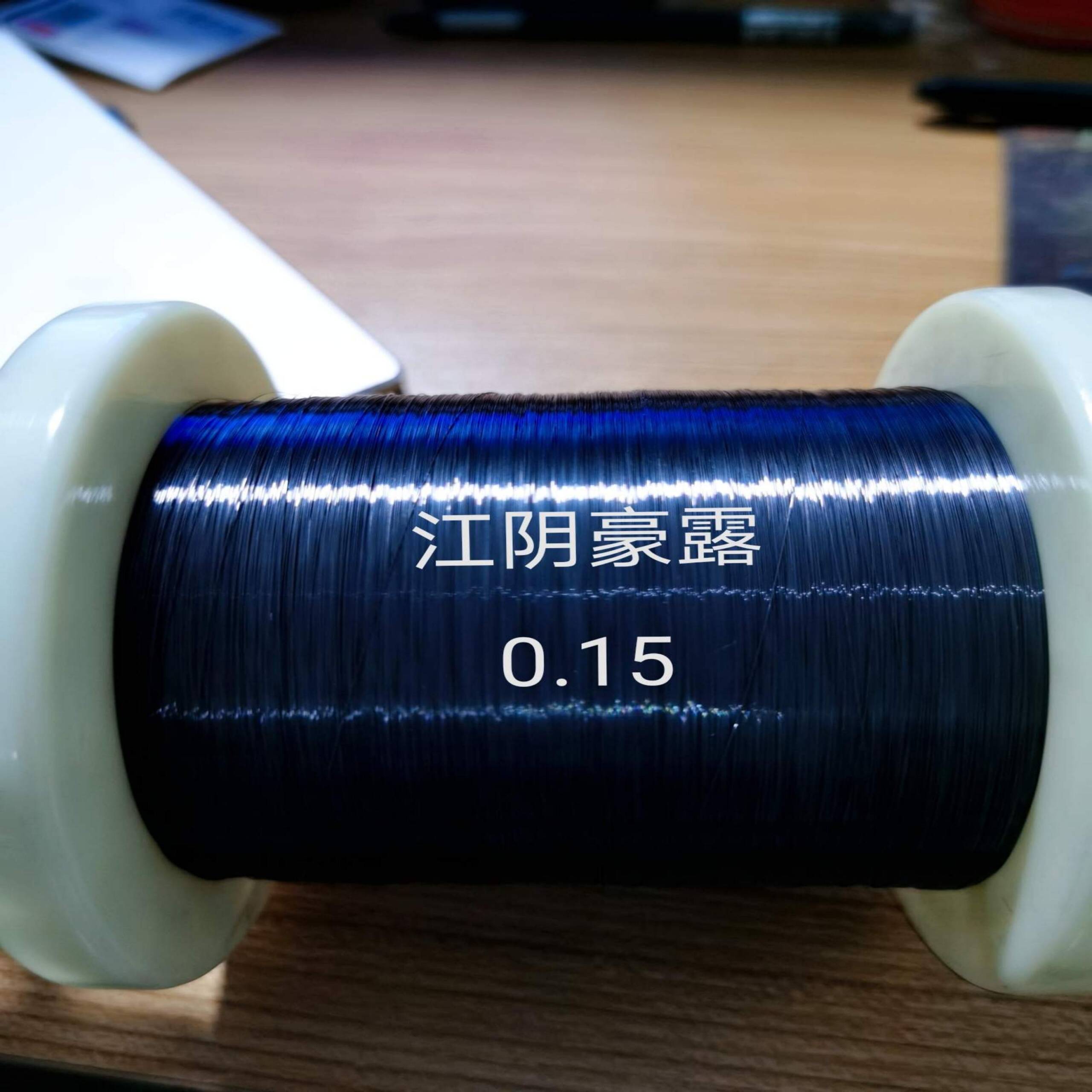

Premium Light Oxidized Nickel Titanium Wire 0.15mm – Advanced Shape Memory Alloy for Precision Applications

Material Overview – High-Quality Nitinol Wire:

Our 0.15mm wire is manufactured using superior-grade nickel titanium, an advanced alloy celebrated for its outstanding shape memory effect and exceptional superelasticity. This premium material, often referred to as niti alloy, delivers excellent flexibility and durability essential for innovative medical devices and industrial applications.

Surface Finish – Controlled Light Oxidation:

Featuring a smooth, uniform oxide layer formed during processing, this finish enhances biocompatibility and corrosion resistance. It reduces friction for smooth device operation in critical environments.

Ultra-Fine Diameter with Tight Tolerances:

Precision manufacturing ensures the 0.15mm wire meets exact size specifications, perfect for intricate devices like micro springs, guidewires, and micro-actuators requiring consistent performance.

Why Choose Our Light Oxidized Nitinol Wire?

Exceptional Elasticity and Fatigue Resistance:

This wire bends extensively and returns to its original shape without damage, ensuring durability in dynamic applications.

Shape Memory Capabilities:

Engineered to “remember” programmed shapes, the wire responds instantly to heat, enabling innovative thermal actuators and self-adjusting components.

Medical-Grade Surface for Safety:

The oxidized finish complies with stringent biocompatibility standards, making it suitable for implants and surgical tools.

Reliable Quality Control:

Every batch undergoes rigorous testing to guarantee purity, precise dimensions, and compliance with ASTM and ISO standards.

Expertise and Compliance in Manufacturing

Our production process strictly follows ASTM F2063 and ISO 13485, ensuring certified, traceable wire that meets RoHS regulations. We focus on delivering consistent quality and performance to support your most demanding projects.

Manufacturing Expertise & Quality Control for Niti Alloy Wire

Our advanced processes meet ASTM F2063 and ISO 13485 standards. We ensure traceability, purity, and compliance with RoHS, delivering reliable, certified niti alloy wire.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.