Description

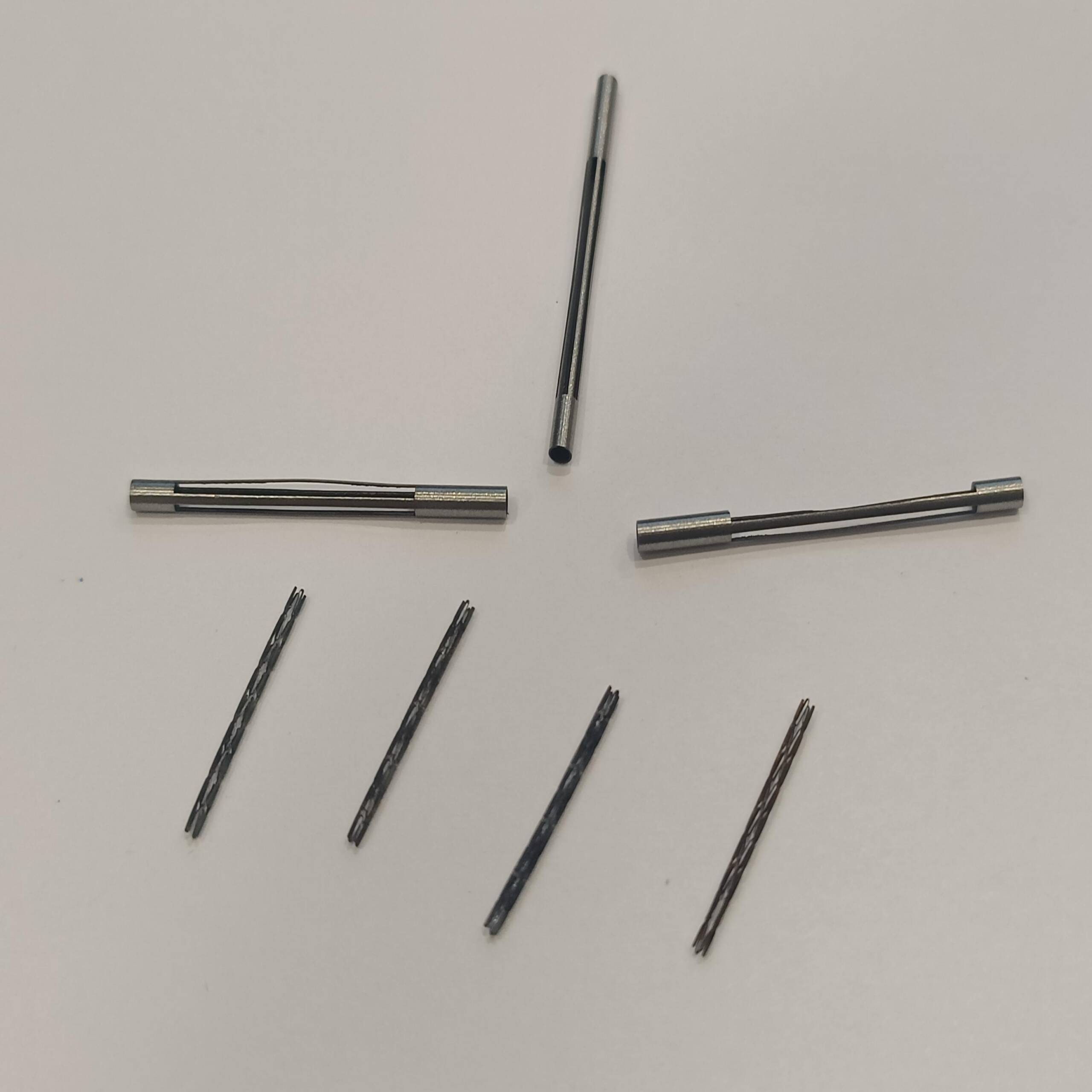

Medical Nitinol Spring Tubing: Corrosion-Resistant Precision for Advanced Devices

Unlock Flexible Innovation in Minimally Invasive Healthcare

Our medical Nitinol spring tubing offers corrosion resistance, superelasticity, and precision manufacturing—making it ideal for today’s most advanced medical devices. Crafted using high-grade Superelastic Nitinol alloys that meet ASTM F2063 standards, this tubing is engineered for use inside the human body, ensuring long-term safety, biocompatibility, and performance.

Engineered for Versatility: Tailored Sizes and Shapes

We provide a wide diameter range, starting from ultra-fine sizes as small as 0.05 mm, perfect for micro-scale instruments and delicate procedures. Larger diameters are also available, up to several millimeters. Custom wall thicknesses and cross-sectional shapes are offered to support your unique design requirements—whether you’re prototyping or scaling production.

Precision Performance in Demanding Medical Applications

Our corrosion-resistant Nitinol tubing supports a wide range of critical medical applications:

-

Guidewires & Catheters – Enables smooth navigation through complex vascular paths.

-

Stents & Delivery Systems – Provides flexible yet durable frameworks.

-

Endoscopic Tools – Powers agile, responsive instruments for minimally invasive surgery.

-

Orthodontic Archwires – Applies gentle and consistent pressure for effective alignment.

-

Surgical Instruments – Builds robust, fatigue-resistant parts for robotic and laparoscopic tools.

-

Neurological Devices – Offers unmatched flexibility and miniature sizing for brain and nerve procedures.

-

Drug Delivery Systems – Enables advanced, implantable therapeutic mechanisms.

Why Choose Our Medical Nitinol Spring Tubing?

-

Superelasticity – Outperforms stainless steel in bending flexibility; always returns to original shape.

-

Enhanced Fatigue Resistance – Withstands countless bending cycles without cracking or failure.

-

Biocompatibility Enhanced – Surface-treated (electropolished, chemically etched) for optimal tissue interaction.

-

Superior Corrosion Resistance – Performs reliably in saline, body fluids, and harsh internal environments.

-

CT & MRI Compatibility – Produces minimal imaging interference, allowing accurate post-op diagnostics.

Nitinol Innovation: Engineered for Smarter Medical Solutions

Nitinol represents a transformative shift in medical engineering. Its unique combination of strength, shape memory, and tissue compatibility empowers engineers to develop smaller, safer, and more effective devices. Whether it’s accessing narrower anatomical pathways or performing reliably over years of implantation, our medical nitinol spring tubing delivers game-changing possibilities.

Partner with Us to Shape the Future of Healthcare

Demand more from your components. Our corrosion-resistant medical Nitinol spring tubing is crafted to meet the highest standards in modern medicine. From tight tolerance control to biocompatible finishes, we support your mission to innovate.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.