Description

Product Overview

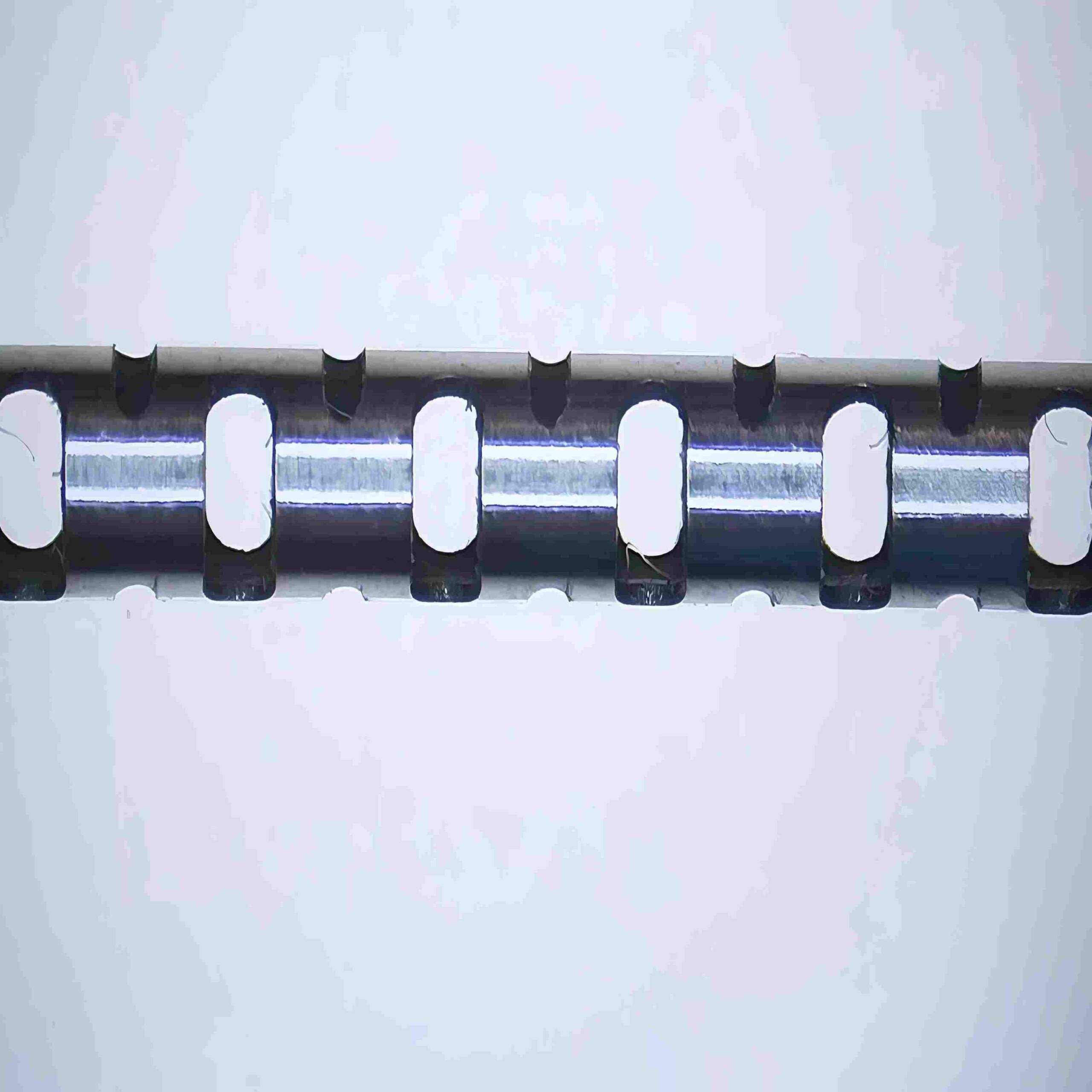

We build custom Nitinol Laser Cutting Tubes to fit what different industries require. This tube uses top-grade nitinol, so it stays reliable when you use it. It delivers precise cuts—ones that meet strict size rules every single time. You’ll find it works great for medical tools, industrial parts, and other key uses too.

Material of Nitinol Laser Cutting Tube

Our Nitinol Laser Cutting Tube uses pure nitinol—no extra additives. This nickel-titanium mix has two big strengths: shape memory and superelasticity. With shape memory, it goes back to its original form once it’s heated. Superelasticity lets it bend way far without getting permanently messed up. These two things together make the tube flexible but still tough enough for everyday use.

What Are the Problems with Nitinol?

Nitinol has some common challenges. First off, it costs more than regular metals—like steel—and that can make project budgets go up. Then, it’s tough to machine; standard cutting tools usually can’t get smooth edges. And third, it can rust in harsh spots, like places with lots of moisture. But our Nitinol Laser Cutting Tube fixes some of these problems. We use advanced laser cutting tech to make sure cuts are precise and smooth. We also put a protective coating on it to lower the chance of rust.

Which Is More Durable, Nickel Titanium or Stainless Steel?

Nickel titanium and stainless steel have different durability strengths. Nickel titanium excels at fatigue resistance—it can handle repeated bending (like in medical catheters) without breaking. On the other hand, stainless steel is stronger for heavy-load tasks, such as supporting weight in industrial frames. For applications that need frequent shape changes, nickel titanium is more durable. For uses that require high static strength, stainless steel is a better choice. Our tube leverages nickel titanium’s fatigue resistance to last longer in dynamic use cases.

Why Is Nitinol Suitable for Surgical Use?

Nitinol is ideal for surgical use for three main reasons. First, its shape memory lets surgeons pre-shape the tube before surgery; once inside the body, it warms up and returns to the needed form. Second, it is biocompatible—this means it does not trigger harmful reactions with body tissues. Third, its flexibility matches the softness of human organs, so it won’t cause damage during movement. Our Nitinol Laser Cutting Tube meets all surgical safety standards, making it a reliable choice for medical procedures.

Diameter Range of Nitinol Laser Cutting Tube

We provide a wide diameter range to fit different needs. The smallest diameter we do is 0.5mm—perfect for tiny surgical tools like micro-catheters. The biggest one we offer is 20mm, which fits larger industrial parts well. And if your project needs a size that’s not in this range, we can customize it for you. Just tell us exactly what you need, and we’ll tweak the tube to match that.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

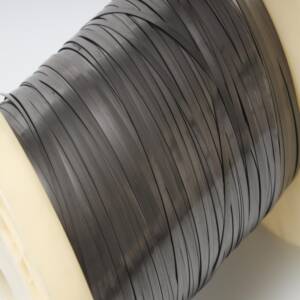

Nitinol Flat wire– Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube -engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.