Description

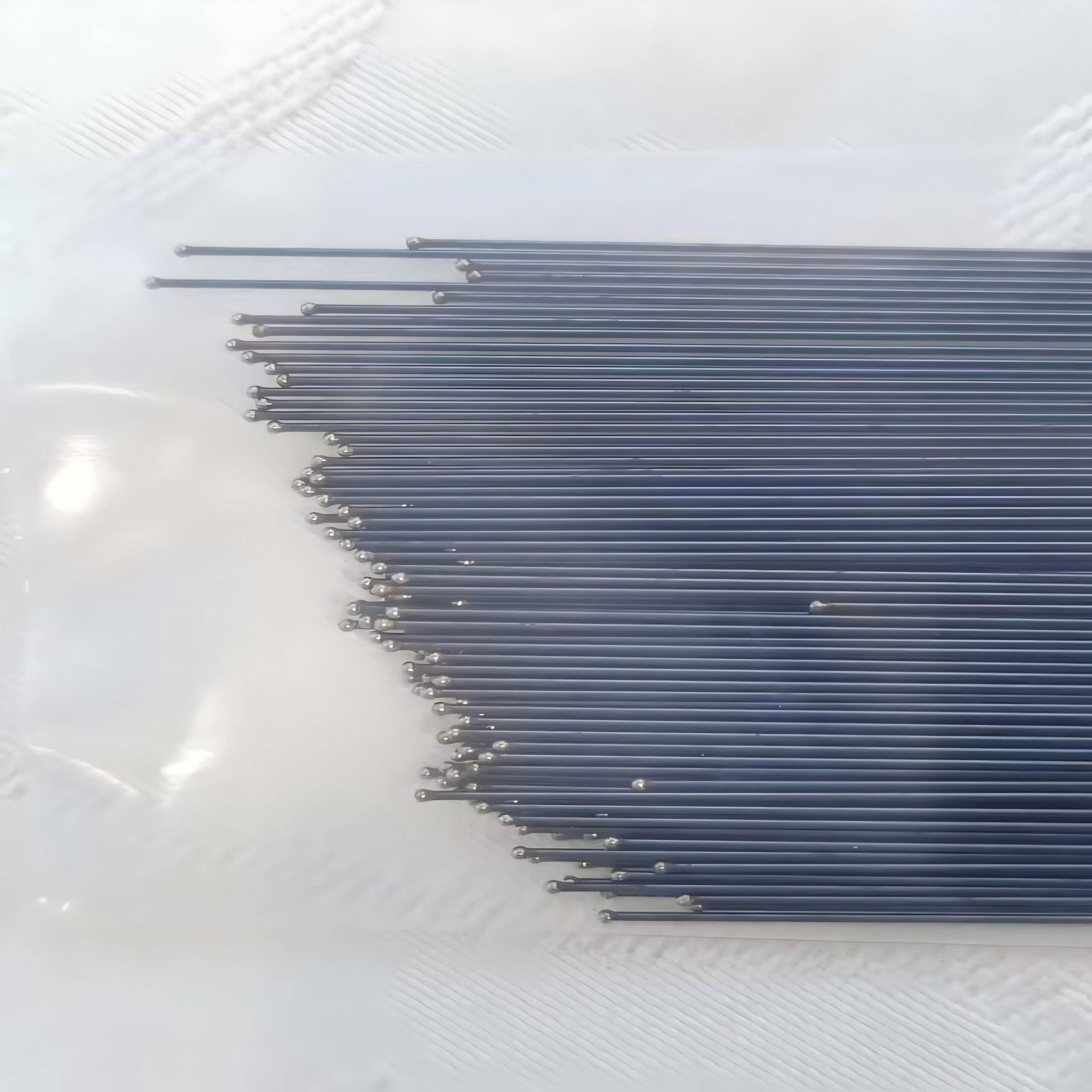

Nitinol Mandrel and Wire | High-Performance Nickel-Titanium Alloy Solutions

Our Nitinol Mandrel and Wire products feature a advanced nickel-titanium alloy. This special material provides a unique combination of superior properties. It is perfect for demanding medical and industrial applications. The product line guarantees exceptional performance, reliability, and durability.

Superior Material Benefits

Nitinol delivers an outstanding balance of high strength and excellent flexibility. The material shows incredible resistance to fatigue and corrosion. This ensures long-term reliability in even the most challenging environments. Our Nitinol Mandrel is a smart choice for precision tooling and component manufacturing.

Addressing Common Nitinol Questions

We provide clear answers to frequent questions about nickel-titanium alloys.

What are the problems with nitinol?

The main considerations involve nickel release and precise manufacturing control. Our company solves these problems with strict process management. We use advanced melting and forming technology. This guarantees a consistent, high-quality nitinol wire with minimal nickel release.

Nickel Titanium vs. Stainless Steel Durability

Nitinol offers greater durability for applications requiring movement and flexibility. It provides exceptional fatigue resistance and superelasticity. A nitinol mandrel can endure repeated stress and bending without deforming. Stainless steel is more rigid and can fail under similar cyclic loads. Nitinol also demonstrates better corrosion resistance in many environments.

Why is nitinol suitable for surgical use?

Two key properties make Nitinol ideal for surgery: Shape Memory and Superelasticity.

-

Shape Memory Effect: A nitinol mandrel or device can be compressed at room temperature. Inside the human body, it gently returns to its original shape. This enables minimally invasive surgical procedures.

-

Superelasticity: Nitinol wire can bend and flex extensively without permanent kinking or breaking. This is vital for guidewires and other flexible surgical instruments.

Precision Product Specifications

We manufacture our Nitinol Mandrel and Wire to the highest quality standards. They are ideal for medical devices, industrial tooling, and research projects.

-

Diameter Range: We offer a comprehensive selection from 0.05 mm to 2.0 mm. Our production ensures tight tolerances and consistent performance across all sizes.

Choose our Nitinol Mandrel and Wire for a smart, strong, and reliable material solution. Experience the benefits of this revolutionary alloy.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.