Description

Nitinol Spring Technology That Performs | MDC Precision Springs

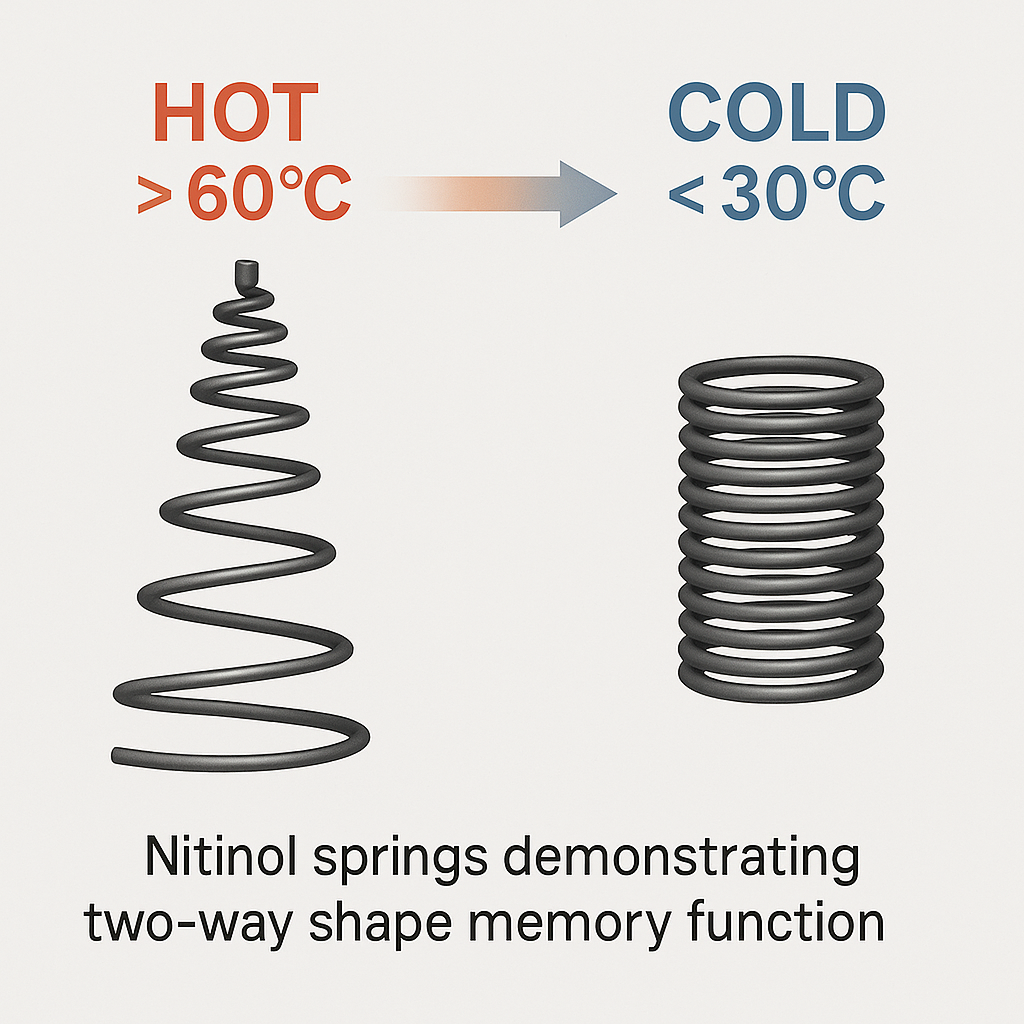

At MDC, we design and manufacture the next generation of Nitinol springs — smart, responsive, and built to perform. Crafted from a high-grade Nickel-Titanium alloy, every Nitinol spring we produce exhibits extraordinary properties: Shape Memory and Superelasticity. These advanced springs return to their original shape after bending or compression, making them ideal for high-precision, high-performance applications. This is not just a spring. It’s engineered intelligence.

Premium Superelastic Nitinol Springs for Advanced Applications

Our springs are made using top-tier superelastic Nitinol grades, including SE508. These grades allow the springs to deform under stress and return completely to their original shape — all without permanent deformation.

Key benefits of our Nitinol springs include:

-

High flexibility and energy absorption

-

Thermal-triggered shape memory response

-

Reliable, repeatable actuation under stress

-

Corrosion resistance in saline or chemical environments

-

Medical-grade biocompatibility

Nitinol Spring Wire Diameters for Every Application

MDC manufactures Nitinol spring wire in a wide range of diameters to suit diverse design needs:

-

Ultra-Fine (0.05 mm) – For micro-scale medical components

-

Fine (0.10–0.50 mm) – For sensors and small electronic devices

-

Standard (0.50–2.00 mm) – Widely used in medical and industrial systems

-

Large (up to 10.0 mm) – Suitable for aerospace, robotics, and automotive

We also provide custom spring diameters tailored to your project’s specifications.

Where Nitinol Springs Excel: Core Application Fields

Explore how MDC’s Nitinol springs enable innovation across sectors:

Medical & Surgical Applications

Used in stents, guidewires, implants, and minimally invasive devices, Nitinol springs ensure safe, reliable, and repeatable function — all while meeting the most stringent biocompatibility standards.

Electronics & Sensors

Deliver smooth electrical contact, repeated actuation, and miniaturized force in compact spaces — ideal for smart electronics and wearable devices.

Aerospace & Automotive Engineering

From fluid valves to vibration dampers, Nitinol springs withstand extreme temperatures and fatigue while contributing to weight reduction.

Industrial & Energy Systems

In robotic tools, couplings, seals, and downhole equipment, our springs offer fail-safe function and cycle longevity, even in corrosive or high-pressure environments.

Why MDC Nitinol Springs Lead the Industry

-

Shape Memory Function: Springs that “remember” and return when triggered by heat

-

Superelastic Response: Flexes far, snaps back immediately

-

Long Fatigue Life: Built to last through millions of cycles

-

Excellent Corrosion Resistance: Reliable in bodily fluids, chemicals, and seawater

-

Medical Compliance: Fully biocompatible for surgical and implant use

-

Fully Customizable: Designed to match your specifications, from force to form

-

Trusted Expertise: Decades of Nitinol and spring manufacturing experience

Why Isn’t Nitinol Used Everywhere?

Despite its benefits, Nitinol spring technology presents challenges:

-

Higher Material Cost than traditional steels

-

Specialized Processing for forming and heat treatment

-

Engineering Learning Curve for first-time users

-

Joining Difficulty to other metals

-

Tight Composition Tolerances required for reliability

MDC Overcomes the Barriers to Nitinol Adoption

We simplify the complexity of Nitinol spring production:

-

Complete Manufacturing Control — from raw wire to finished part

-

Collaborative Design Services — guiding engineers through best practices

-

Strict Quality Assurance — ensuring batch-to-batch consistency

-

Value-Focused Engineering — maximizing ROI through smart design

Let’s Innovate Together — Request Your Custom Nitinol Spring

Ready to experience the intelligent behavior of Nitinol springs? Partner with MDC to create components that react, respond, and reset.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.