Description

-

Precision Nitinol Tube: Shape Memory Solutions for Advanced Applications

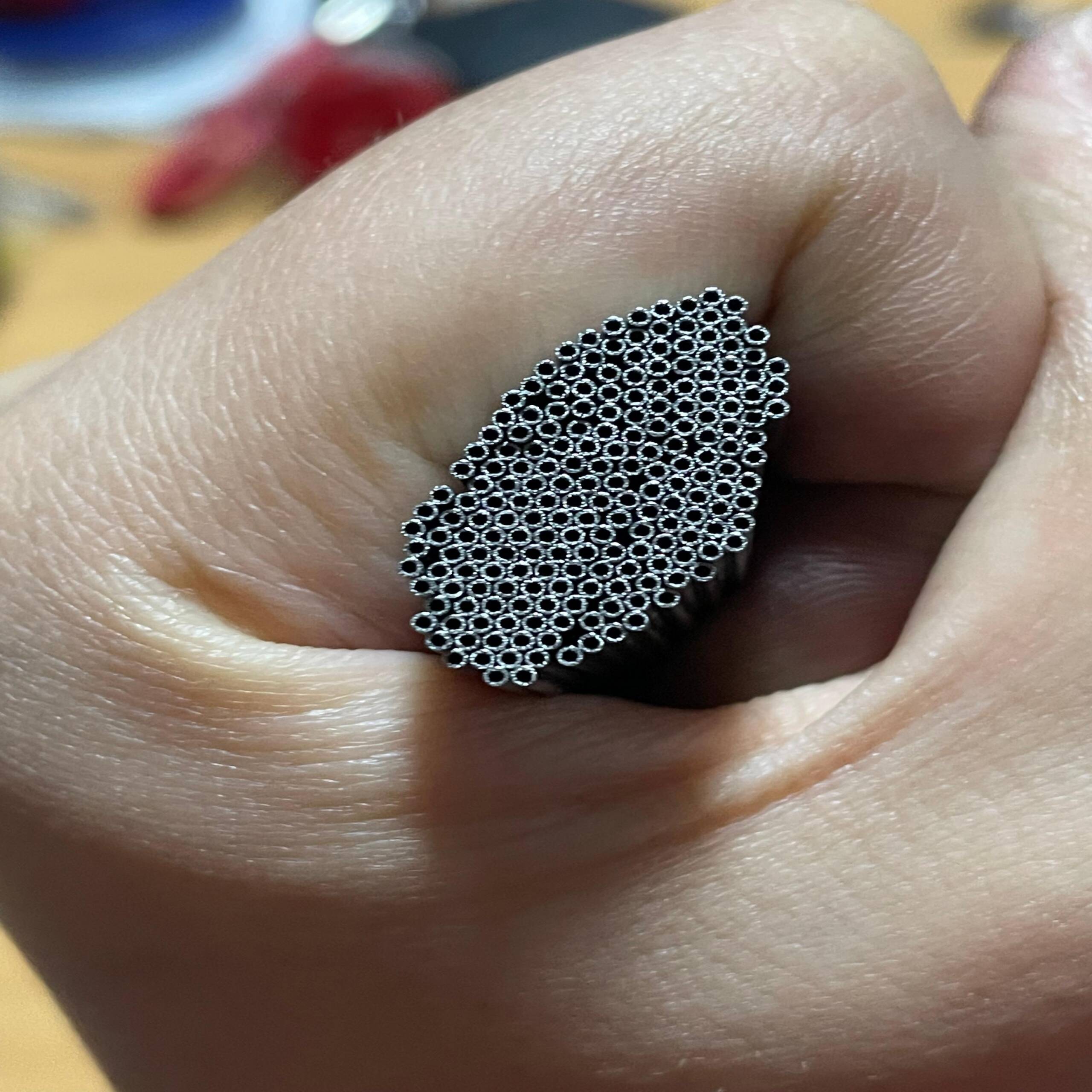

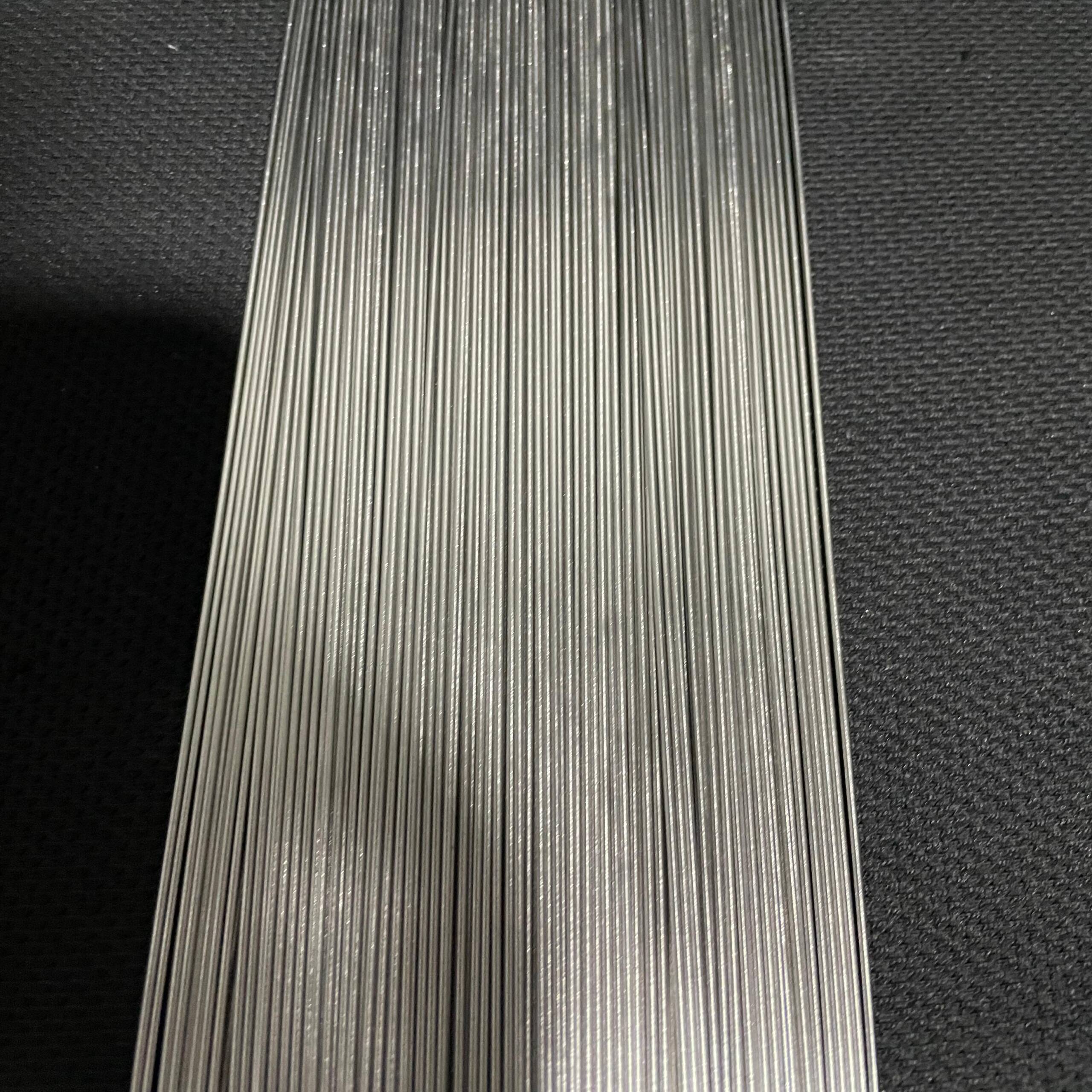

Generally speaking Nitinol tubes—engineered from an exact alloy composition of 55% nickel and 45% titanium—are revolutionizing performance standards in next-generation medical devices. Notably, by leveraging their shape memory and superelastic properties, these advanced tubes automatically return to their original form when heated. Therefore, they have become essential components in life-saving, minimally invasive procedures. Moreover, thanks to our proprietary process innovations, we now offer Nitinol tubing with outer diameters up to 16 mm—significantly unlocking new dimensions in device design and function.

Unmatched Precision: Medical-Grade Nitinol Tube Specifications

As a pioneer in the field, our vertically integrated manufacturing system ensures strict quality control and engineering excellence. In particular, we deliver tubing that meets the most demanding medical standards:

-

✓ Concentricity ≤ 0.01 mm – for precise control of device trajectories

-

✓ Wall tolerance ± 0.0075 mm – aerospace-grade dimensional stability

-

✓ Medical-grade Nitinol – ASTM F2063-compliant feedstock

-

✓ OD range: 0.18–16 mm, with fully customizable options

-

✓ Wall thickness from 0.05 to 2.5 mm – from ultra-thin to high-strength designs

-

✓ Inner fold depth < 0.5 μm – ensuring fluid dynamic efficiency

-

✓ Full traceability – enabled by proprietary, in-house production systems

As a result, these features combine to provide exceptional performance and safety in high-precision applications.

Why Choose Nitinol Tubes Over Conventional Tubing?

Compared to stainless steel or polymer alternatives, Nitinol tubes offer several transformative advantages. First of all, they exhibit:

1️⃣ 8% strain recovery – delivering up to 300% greater flexural endurance in steerable catheters

2️⃣ Body-temperature activation (Af = 37 ± 2°C) – precisely customized for human physiology

3️⃣ Nanofinished surfaces (Ra ≤ 0.05 μm) – significantly reducing fluid drag by up to 40%, thereby improving flow and accuracyConsequently, Nitinol tubing enables performance levels that conventional materials simply cannot match.

Smart Applications Across Medical Fields

Thanks to their unique mechanical and thermal properties, Nitinol tubes are essential in a wide range of medical applications. For example:

-

Peripheral stents – benefit from self-expanding, shape-memory deployment

-

Cardiac occluders – adapt seamlessly to dynamic cardiac anatomy

-

Neurointerventional catheters – provide enhanced torqueability for delicate procedures

-

Orthopedic implants – meet ISO 10993 biocompatibility standards for safe, long-term use

Altogether, these applications showcase the versatility and clinical importance of Nitinol.

Frequently Asked Questions (FAQs)

Q1: Why use Nitinol tubes in medical devices?

Nitinol combines shape memory with superelasticity, enabling both transient deployment and long-term structural integrity—ideal for implantable and flexible tools.Q2: How is fatigue resistance achieved?

We use VAR-melted feedstock and a multi-stage cold-working process. Consequently, our tubes demonstrate fatigue life exceeding 10 million cycles.Q3: What are the lead times for custom sizes?

Standard outer diameters ship within 72 hours. On the other hand, ultra-thin wall tubing (≤ 0.1 mm) requires 15 business days.Q4: Do you offer additional services?

Yes. In addition to raw tubing supply, we provide laser cutting, shape-setting, and complete OEM component solutions.

The Future of Medical Innovation Starts with Nitinol Tubes

In summary, Nitinol tubes represent a cornerstone in the evolution of smart medical devices. With ongoing advancements in materials engineering, they continue to push the boundaries of minimally invasive technology. Ultimately, they empower clinicians to design safer, more effective tools—all while reducing complexity and procedural risk.

-

▸ Material Analysis: Complimentary DSC testing

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account: Facebook

Reviews

There are no reviews yet.