Description

-

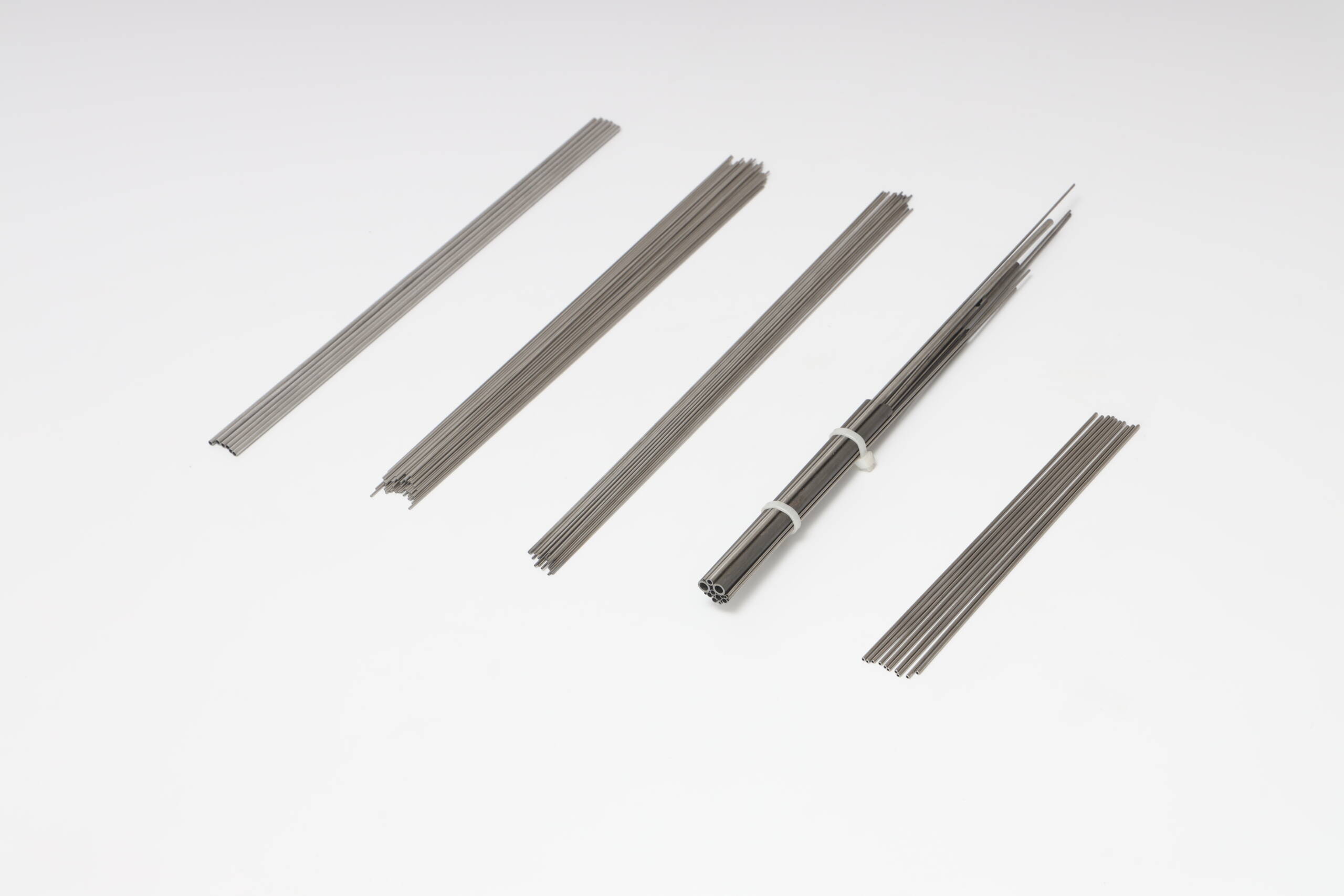

Nitinol Tubing Solutions for Cutting-Edge Medical Innovation

Nitinol tubing is transforming next-generation medical device development. At Confluent Medical Technologies, we combine decades of expertise with vertically integrated U.S. manufacturing to produce high-performance nitinol tubing and components. By controlling every step from raw wire to finished product, we ensure unmatched quality, consistency, and supply chain reliability—earning our place as a trusted partner across the medical device industry.

Precision Engineering by Confluent Medical Technologies

Confluent’s commitment to precision engineering empowers our customers to accelerate development and scale efficiently. Our capabilities include:

-

Rapid prototyping alongside mass production scalability

-

Integrated gun drilling for superior wall uniformity (±0.0005″)

-

Diameter range from 0.5mm to 10mm (0.020″–0.400″)

-

Availability in SE508 and SE508 ELI medical grades

-

Industry-leading lead times with both stock and custom options

Moreover, our dedicated materials science team continually enhances process control and mechanical performance, ensuring our nitinol tubing meets the demands of today’s most advanced clinical applications.

Advancing Hypotube Performance with Edgetech Industries

Meanwhile, Edgetech Industries delivers cutting-edge superelastic nitinol tubing tailored for high-precision applications.

Thanks to advanced manufacturing processes, we support the production of

-

-

- light cutting designs including spiral, radial and custom geometries

-

OD step grinding for integrated catheter transitions

- Ultra-thin walls reaching down to 0.005mm

In addition, Edgetech maintains a responsive inventory model, enabling quick turnaround for cardiovascular and urological applications requiring specialized tubing.

Why Nitinol Tubing Excels in Minimally Invasive Devices

Due to its unique material properties, nitinol tubing offers several key benefits:

→ High kink resistance and optimized torque response

→ Smooth navigation through complex anatomy

→ Enhanced pushability for PTCA and structural heart therapiesAlthough nitinol remains our core strength, we also process stainless steel to support hybrid and multi-material device architectures.

Beyond Healthcare: Industrial and Cross-Sector Applications

While medical innovations drive demand, nitinol tubing also powers performance in other industries.

Medical Device Applications

▸ Catheter guidance and delivery systems

▸ Stent deployment platforms

▸ Neurovascular and orthopedic implants

▸ Precision surgical instrumentsIndustrial Use Cases

▸ Aerospace conduit solutions

▸ Robotic actuators and motion systems

▸ Smart pipeline connectors

▸ Oil, gas, and energy deployment toolsAdditionally, nitinol’s shape memory and superelasticity make it ideal for use in dynamic, load-bearing, and safety-critical applications across sectors.

Strategic Partnership Advantages

Significantly, our collaboration between Confluent and Edgetech delivers dual-source security and engineering excellence. Clients benefit from:

-

Redundant nitinol tubing supply chains for reduced risk

-

Engineering support from concept through validation

-

FDA- and MDR-compliant traceability on all tubing materials

For detailed specifications, application insights, or prototyping collaboration, visit our Nitinol Resources Page.

Reviews

There are no reviews yet.