Description

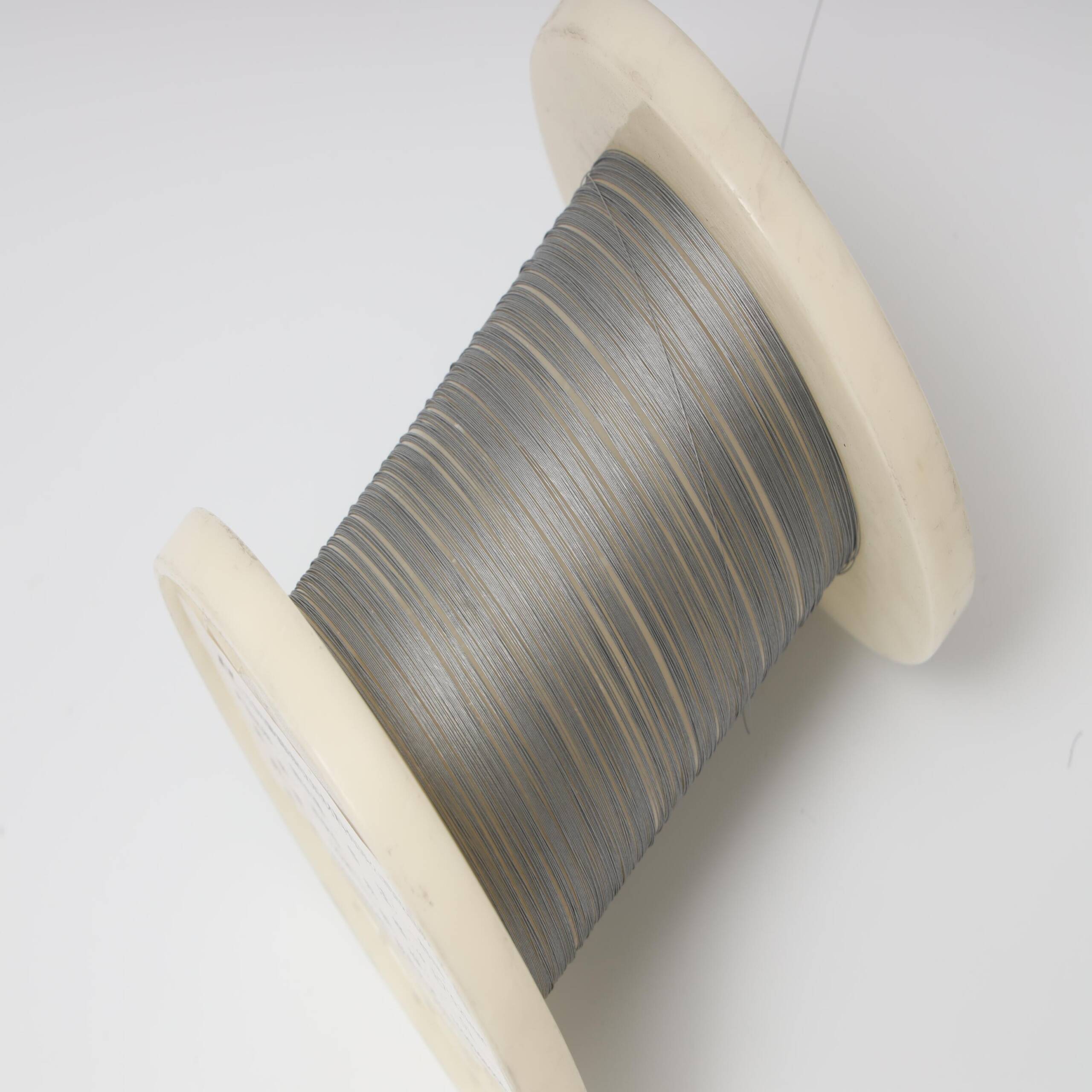

Explore Nitinol Uses with Our 1×7 Clean Oxidized Nickel Titanium Rope – 0.889mm Superelastic Precision

Unlock the full potential of advanced material science with our 1×7 Clean Oxidized State Nickel Titanium Rope, precision-engineered at a 0.889mm diameter. Made from premium superelastic Nitinol, this high-performance rope is your solution for applications requiring exceptional flexibility, fatigue resistance, and kink-proof durability. Discover why “nitinol uses” are expanding across industries from medical to aerospace.

The Smart Material Behind It All: Superelastic Nitinol

Nickel + Titanium = Nitinol

Composed of nickel and titanium, Nitinol offers two remarkable characteristics—superelasticity and shape memory.This allows the rope to deform under stress and return to its original shape without permanent deformation.

Superelasticity in Action

Nitinol stretches or bends far beyond what conventional metals can tolerate, then recovers instantly. This feature is crucial for dynamic, load-bearing, or shape-critical components.

Shape Memory Effect

When heated, Nitinol reverts to its “memorized” shape. Although our rope is optimized for superelastic behavior at ambient and body temperatures, this shape memory feature opens up further engineering opportunities.

Biocompatible and Corrosion-Resistant

Nitinol’s biocompatibility makes it ideal for medical devices. Its clean oxidized surface offers superior corrosion resistance—especially important in clinical or harsh industrial settings.

Precision Engineering: 1×7 Clean Oxidized Rope Design

1×7 Construction for Strength and Flexibility

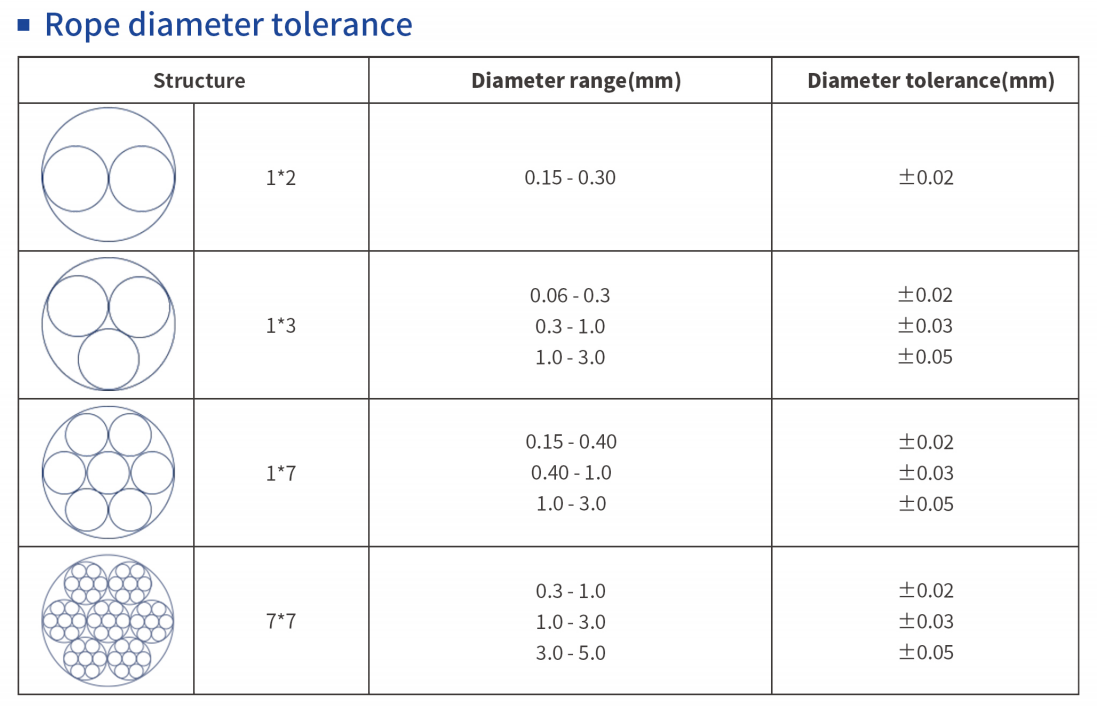

Seven individual superelastic Nitinol wires are twisted into a 1×7 formation—one core wire surrounded by six helically wound strands. This design ensures enhanced tensile strength, fatigue resistance, and consistent torque transmission.

Clean Oxidized Surface Treatment

Each wire undergoes precision surface oxidation for a clean, uniform finish. The oxidized state improves corrosion resistance, visual consistency, and provides subtle surface texture for better handling or bonding.

Nitinol Uses: Medical, Industrial, and Beyond

Nitinol is revolutionizing engineering. Its unique behaviors allow it to outperform traditional metals in several sectors. Here’s how our rope supports key nitinol uses:

Medical Applications (Core nitinol uses):

-

Guidewires: Deliver exceptional flexibility and precise torque response for navigating intricate vascular pathways.

-

Catheters: Enhance maneuverability and pushability in minimally invasive tools

-

Orthodontics: Maintain steady forces for teeth alignment

-

Stent Delivery: Improve precision in vascular stent placement

-

Surgical Robotics: Enable flexible, responsive robotic motion

Industrial Applications:

-

Actuators & Robotics: Enable motion systems driven by heat-triggered shape recovery

-

Sensors: Respond to stress or temperature shifts with predictable behavior

-

Fluid Flow Valves: Control systems in aerospace, oil, and gas

-

Precision Mechanisms: Ensure repeated motion cycles without material failure

Consumer & Aerospace:

-

Eyewear Frames: Flexible, durable memory frames

-

Antennas: Flexible, kink-resistant signal structures

-

Aerospace Mechanisms: Actuators for satellite or UAV component deployment

-

Vibration Control: Passive dampening in mission-critical assemblies

Why Engineers Choose Nitinol

-

8%+ Elastic Strain: Bend it far—Nitinol returns to form, unlike steel

-

Kink Resistance: Maintain open pathways, especially in vascular systems

-

Steady Force Delivery: Ideal for medical devices needing consistent output

-

High Fatigue Life: Withstand millions of cycles

-

MRI-Compatible: Safe and non-magnetic for sensitive environments

Get Started: Experience the Best of Nitinol Uses

Our 0.889mm 1×7 Clean Oxidized Nickel Titanium Rope brings high-performance nitinol uses to your fingertips. Whether you’re developing a next-gen catheter or a reliable aerospace actuator, this rope is engineered to excel.

•Mechanical properties

Upper platform |

Tensile |

Elongation |

Residual deformation |

Phase transition |

>350MPa |

>1000MPa |

>10% |

<0.5% |

-10~20℃ |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.