Description

Nitinol Wire – Advanced Shapes – Memory Alloy for Precision Engineering

We specialize in manufacturing Nitinol products, a high-performance shape-memory alloy engineered to deliver unmatched flexibility and durability across precision applications. Ideal for medical, industrial, and consumer technologies, our NiTi wire combines superelasticity with precision engineering, offering tailored solutions from ultra-fine diameters (as thin as 0.025 mm) to fully customizable transformation temperatures (Af).

Why Ni Ti Wire Excels in Critical Applications

As a superelastic wire alloy, Ni Ti wire functions optimally between 0°C and 40°C, recovering from up to 8% strain without permanent deformation. This unique property, combined with a naturally formed low-friction oxide layer, makes it indispensable in a variety of use cases:

-

High-cycle components: Springs, actuators, shock absorbers

-

Attrition-sensitive systems: fishing tools, minimally invasive surgical equipment

-

Dynamic environments: Antennas and drive mechanisms exposed to repetitive motion

Medical-Grade vs. Industrial-Grade Nitinol Wire Solutions

We offer two specialized Ni Ti categories tailored to distinct application environments:

Medical-Grade Nitinol Wire

-

ASTM F2063 compliant (54.5–57 wt% Nickel)

-

Biocompatible for implants, stents, and surgical tools

-

Used in precision devices such as orthodontic archwires

Industrial-Grade Nitinol Alloys

-

Customizable NiTi formulations

-

Tunable Af temperatures from -10°C to 110°C

-

Engineered for thermal and mechanical cycling resistance

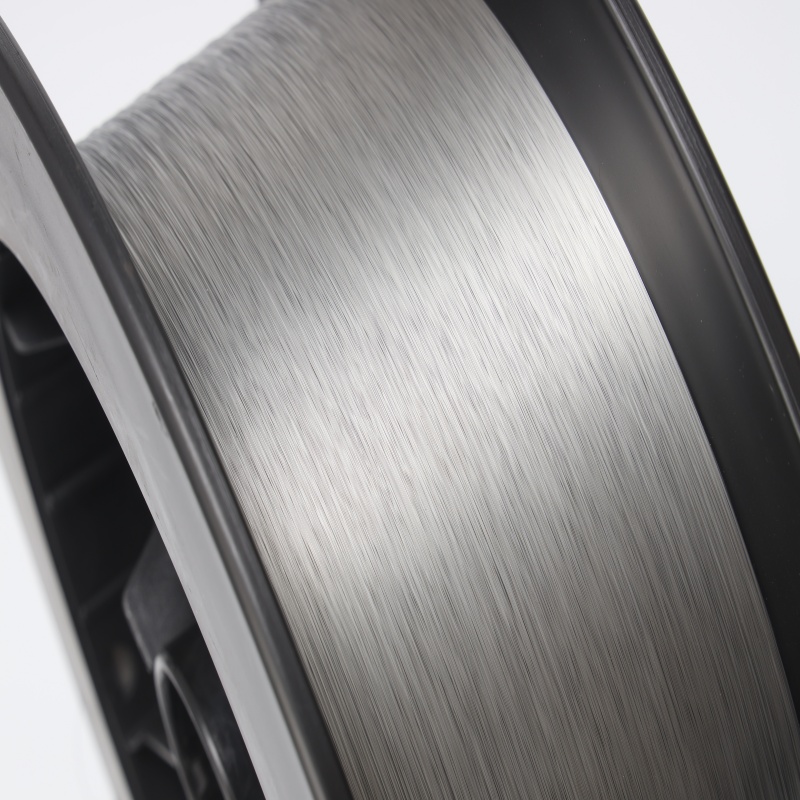

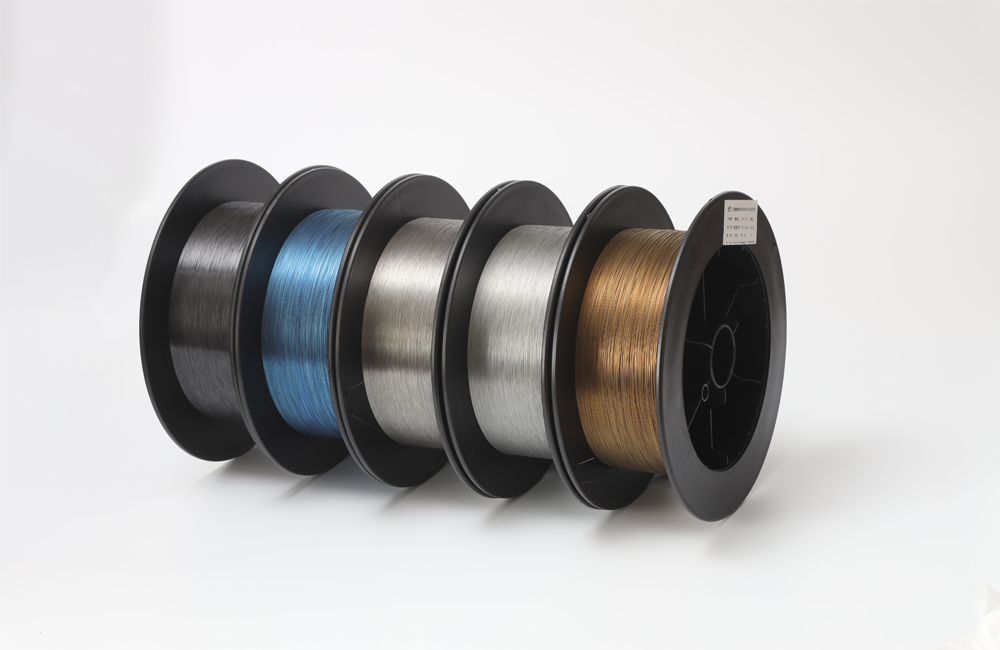

Configurable Nitinol Wire Specifications

Our shape-memory Nitinol wire adapts to diverse performance and design needs through:

1. Dimensional Flexibility

-

Diameter Range: 0.025 mm to 4.0 mm

-

Tolerances: ±0.003 to ±0.025 mm

-

Form Factors: Round, flat, square, and multi-strand ropes

-

Delivery Formats: Straightened, coiled, or spooled

2. Surface Engineering Options

-

Low-friction finishes: Black oxide, pickled

-

Premium finishes: Polished (≥1 mm), chemically cleaned

3. Thermal Customization

We offer precise control over transformation temperatures:

| Application Type | Af Range |

|---|---|

| Medical Devices | 10 ± 10°C |

| Consumer Electronics | 25 ± 5°C |

| High-Temp Industrial Systems | 60 ± 10°C |

Mechanical Performance of Nitinol Wire

Our Nitinol wires are validated under various temperature profiles to ensure consistent mechanical reliability:

| Property | Specification | Testing Conditions |

|---|---|---|

| Tensile Strength | ≥1000 MPa (1350 MPa*) | 10±10°C / -30±10°C |

| Elongation | ≥10% (15%*) | 60±10°C |

| Residual Strain | <0.5% | All operational temperatures |

Cross-Industry Applications of Nitinol Wire

Thanks to its combination of strength, elasticity, and recoverability, Nitinol wire supports innovation across multiple industries:

Medical Innovation

-

Self-expanding stents

-

Temperature-responsive biopsy tools

Consumer Technology

-

Flexible eyeglass frames

-

Anti-kink, shape-retaining fishing lines

Industrial Systems

-

Robotic actuators requiring fatigue resistance

-

Vibration-damping springs for aerospace or automotive systems

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.