Description

Premium Nitinol Wire Rope for Precision Applications

We engineer Nitinol wire rope from top-grade superelastic nickel-titanium alloys, known for exceptional flexibility, strength, and durability. This cutting-edge material bends, twists, and stretches under extreme mechanical stress—yet always returns to its original shape. Its superior elasticity and resistance to deformation make it the preferred choice for high-performance environments.

Wide Diameter Range to Suit Every Purpose

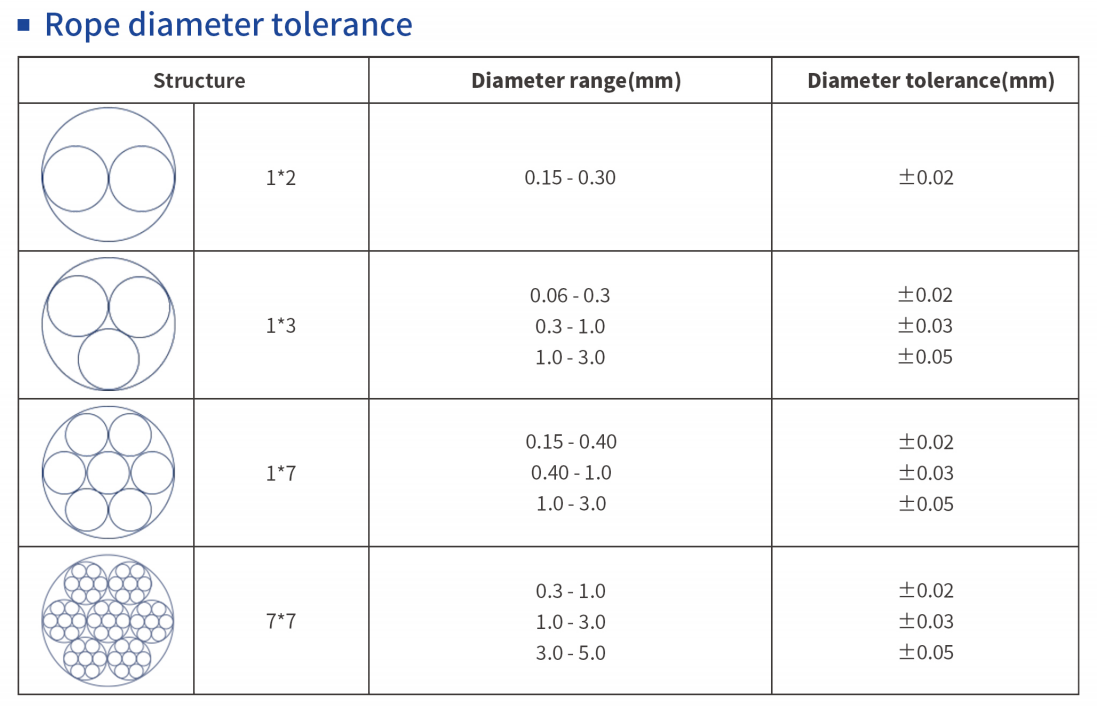

Our Nitinol wire rope is available in a wide range of custom diameters, from ultra-fine 0.1 mm to robust 5.0 mm. Whether you’re working with delicate surgical devices or heavy-duty industrial systems, we offer size solutions tailored to your exact needs. Each rope is manufactured with tight tolerances and quality control to ensure consistent mechanical properties.

Versatile Applications Across Industries

-

Medical Devices: Commonly used in guidewires, stents, and minimally invasive tools. Nitinol resists corrosion in bodily fluids and navigates narrow anatomical paths with ease.

-

Aerospace: Performs flawlessly in satellite deployment systems and components exposed to drastic temperature changes.

-

Robotics: Powers bio-inspired artificial muscles and flexible joints, mimicking the motion of tendons and ligaments.

-

Automotive: Used in thermal-responsive actuators, smart valves, and engine sensors for quick adaptive responses.

-

Consumer Electronics: Adds durability to eyeglass frames, wearables, and self-adjusting antennas.

Why Choose Nitinol Wire Rope?

-

Superelasticity: Extends up to 8x more than steel without permanent deformation. It withstands repetitive bending and crushing.

-

Shape Memory Effect: Responds to heat. Deform it at low temperatures (as low as -22°F) and watch it return to shape at 180°F.

-

Biocompatibility: Safe for long-term use in the human body—trusted in hospitals worldwide.

-

Corrosion Resistance: Remains unaffected by saltwater, acids, and other harsh environments.

-

High Fatigue Strength: Withstands millions of flexing cycles, making it perfect for dynamic applications.

Smart Thermal Activation Range

Our Nitinol wire rope operates dynamically across a broad activation range from -22°F to 180°F. It softens in cold temperatures for manipulation and becomes firm and functional when heated. This makes it ideal for cryogenics, aerospace systems, or engine compartments where adaptability is key.

Upgrade to Nitinol wire rope for a smarter, more efficient future. Replace traditional springs, motors, and hinges with a material that thinks, reacts, and lasts. Whether in surgery, satellites, or smart tech—Nitinol delivers the performance you can count on.

•Mechanical properties

Upper platform |

Tensile |

Elongation |

Residual deformation |

Phase transition |

>350MPa |

>1000MPa |

>10% |

<0.5% |

-10~20℃ |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.