Description

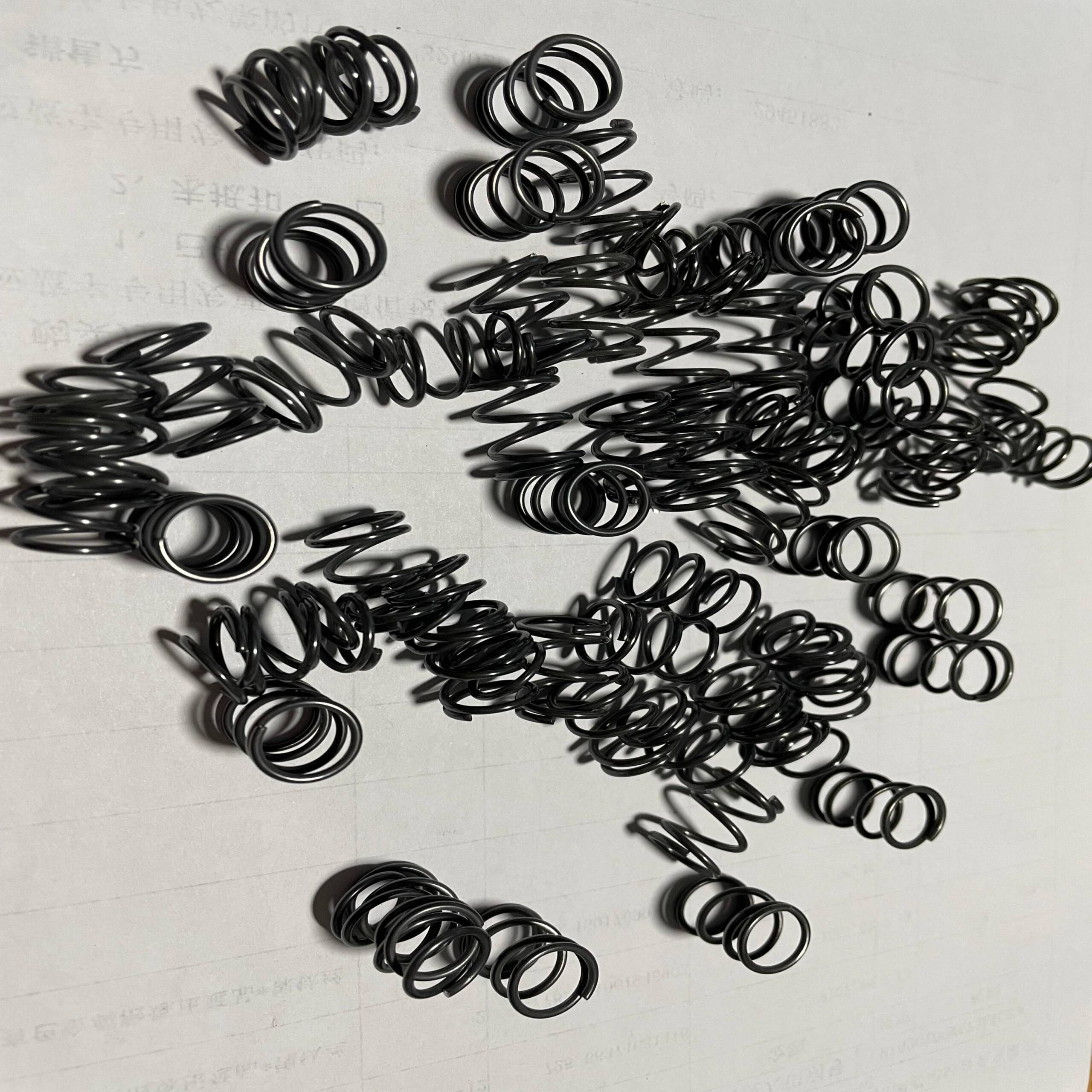

High-Performance Nitinol Wire Spring Solutions for Precision Applications

Smart Material for Demanding Conditions

Our nitinol wire spring products are engineered from high-grade nickel-titanium alloy—commonly known as Nitinol. This advanced material offers unmatched superelasticity and shape memory properties, allowing springs to endure extreme deformation and return to their original form. Additionally, Nitinol’s natural corrosion resistance and excellent biocompatibility make it a top choice for both medical and industrial applications. In many cases, a nitinol wire spring outperforms traditional steel, especially under high-strain or chemically aggressive conditions.

Surface Finishing Tailored to Function

Choose from a variety of finishes to optimize performance. Our standard electropolished finish provides a smooth, bright surface that reduces friction and improves fatigue life. For better grip or adhesion, we also offer etched surfaces. When biocompatibility is a concern, our medical-grade passivation ensures compliance with strict healthcare standards. Custom finishes can also be developed to meet unique application demands, ensuring your nitinol wire spring performs reliably in any environment.

Broad Diameter Range for Maximum Versatility

We manufacture nitinol wire springs in diameters from 0.05 mm (0.002 in) to 2.0 mm (0.08 in), supporting everything from delicate micro-devices to robust mechanical assemblies. Furthermore, we tightly control diameter tolerances to ensure consistency and predictability in spring performance. No matter your size requirement, we likely have the perfect solution.

Application Versatility

Due to their unique properties, nitinol wire springs are trusted across a wide range of industries:

-

Medical Devices – Guidewires, implantable devices, orthodontic springs, endoscopic tools.

-

Electronics – Micro-actuators, probe cards, vibration dampers, switch mechanisms.

-

Aerospace & Automotive – Fuel injector springs, thermal actuators, UAV systems, sensor elements.

-

Industrial Systems – Robotic joints, valve controls, safety releases, thermal triggers.

-

Consumer Products – Eyewear components, wearable devices, sporting goods, thermostats.

-

R&D and Prototyping – Smart mechanisms, micro-robotics, test equipment, custom actuators.

Why Choose Our Nitinol Wire Spring Products?

1. Superelastic Precision

Our nitinol wire springs offer true superelastic performance. They can be stretched or compressed significantly and return to shape immediately, enabling compact, lightweight, and high-efficiency designs.

2. Long-Term Durability

Thanks to their corrosion resistance, these springs are ideal for environments with moisture, chemicals, or bodily fluids. This means longer service life and fewer replacements.

3. Fatigue Resistance

Nitinol’s fatigue resistance surpasses that of stainless steel, especially in cyclic loading. A nitinol wire spring can handle millions of actuation cycles without degradation.

4. Certified Biocompatibility

We use medical-grade Nitinol and certified processes, ensuring our springs meet regulatory standards for medical and dental devices.

5. Intelligent Thermal Response

Design your nitinol wire spring to activate at specific temperatures. With shape memory functionality, it enables smart control in thermal systems and safety applications.

6. Lightweight Strength

Nitinol’s excellent strength-to-weight ratio makes it perfect for modern devices where performance and minimal mass are both essential.

7. Custom Manufacturing Capabilities

We specialize in manufacturing springs with tight tolerances and complex geometries. Whether for a surgical tool or industrial robot, we deliver exactly what you need.

8. Consistent, Tested Quality

Each batch of nitinol wire spring components undergoes rigorous inspection for material composition, dimensional accuracy, and surface quality—ensuring reliable performance.

9. Expert Engineering Support

Our team provides guidance on design, material selection, and optimization. From concept to production, we help you get the best results.

10. Globally Trusted Supplier

Manufacturers worldwide trust our nitinol wire springs in mission-critical applications across aerospace, medical, and electronics industries.

Start Your Project with Proven Nitinol Technology

If you’re looking for durability, elasticity, and precision, our nitinol wire spring solutions offer everything you need. Let us help you create better, smarter, and longer-lasting products. Contact our team today to discuss custom lengths, shapes, and spring forces tailored to your application.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.