Description

Premium 1×7 Black Oxidized Nitinol Rope 0.28mm – Superelastic Research Alloy for High-Performance Applications

Unlock the next frontier of innovation with our Black Oxidized Nitinol Rope (0.28mm, 1×7 construction)—a precision-engineered research alloy built for demanding studies in medical devices, robotics, aerospace, and advanced materials science. With unmatched superelasticity, superior fatigue resistance, and a specialized black oxide surface, this rope is the reliable choice for breakthrough research.

Engineered Core: Medical-Grade Superelastic Nitinol

This rope is built around superelastic Nitinol—an advanced nickel-titanium alloy celebrated for its remarkable shape memory and ability to withstand extreme deformation without permanent damage.The selected grade is optimized for performance near human body temperature—ideal for biomedical research, surgical prototypes, and medical device development. Each batch delivers consistent purity and performance, critical for your sensitive test environments.

Fine Construction: 0.28mm Diameter, 1×7 Strand Design

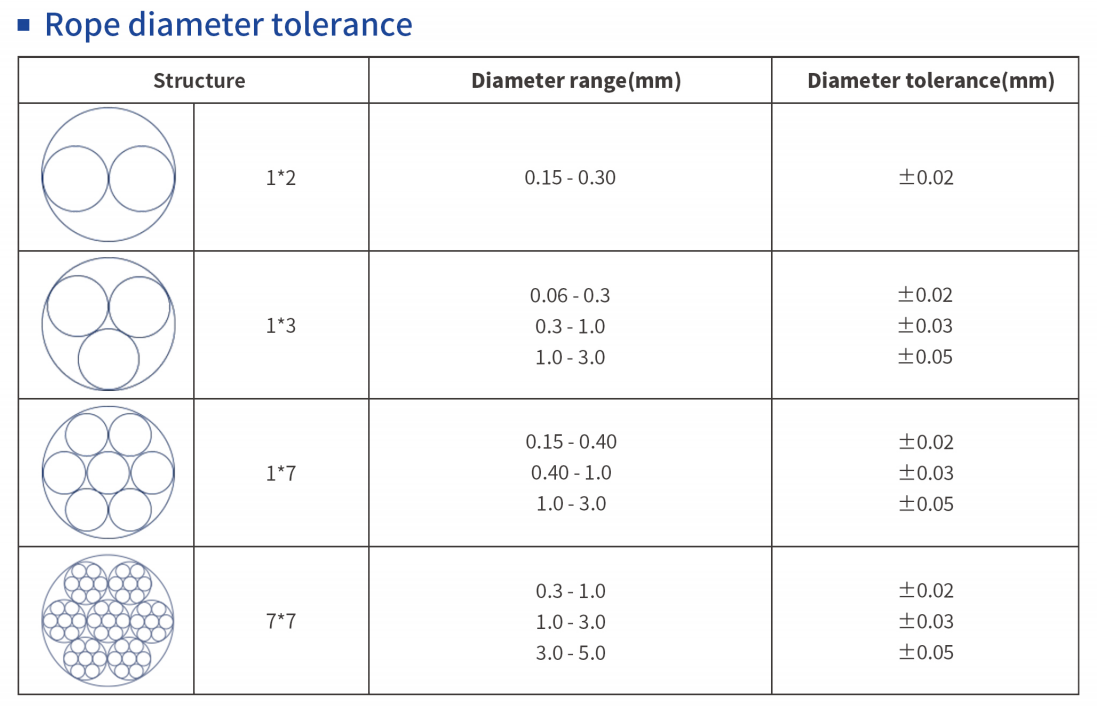

This 1×7 Nitinol rope features a precise 0.28mm outer diameter, making it suitable for miniaturized tools and micro-mechanisms. The structure—one central wire surrounded by six helically wound wires—offers superior strength, flexibility, and smooth force transmission even under extreme bending or twisting. It performs reliably in dynamic systems where motion control and responsiveness are key.

Enhanced Surface: Durable Black Oxide Finish

The rope is treated with a black oxidized surface, offering functional and aesthetic advantages:

-

Greater surface hardness ensures better durability against friction and repeated contact.

-

Improved corrosion resistance in varied testing environments

-

Low reflectivity, ideal for optical testing or stealth-focused designs

-

Textured surface, aiding coating adhesion and enhancing biocompatibility testing

Superelasticity: The Signature of Nitinol

Unlike ordinary metal wires, this superelastic alloy handles extreme deformations—bending, stretching, twisting—then instantly returns to its original shape without residual strain. Its near-constant force output over large deflection ranges supports precise, predictable mechanical behavior.

Whether you’re studying energy absorption, impact damping, or vibration isolation, this rope provides the mechanical versatility your research alloys demand.

Why Researchers Choose Nitinol

-

Shape Memory Effect: Recovers original form when heated above transformation temperature

-

Exceptional Fatigue Resistance: Withstands repeated loading cycles

-

MRI Compatibility: Low interference in imaging environments

-

High Biocompatibility: Suitable for implant and surgical tool R&D

-

Consistent Performance: Reliable results for lab and clinical studies

Target Research Applications

Minimally Invasive Devices

-

Superelastic guidewires, stents, and micro surgical tools

-

Orthodontic systems applying gentle, sustained forces

Micro-Robotics & Actuators

-

Artificial muscles and deployable aerospace components

-

Micro-grippers and prosthetic actuation systems

Sensors & Instrumentation

-

Strain and temperature sensors using shape memory behavior

-

Damping components in precision instruments

Materials & Smart Alloy Studies

-

Austenite–martensite transformation testing

-

Fatigue behavior and corrosion resistance under clinical conditions

Advance Your Research with Premium Nitinol Rope

Our Black Oxidized Superelastic Nitinol Rope (0.28mm, 1×7) offers the flexibility, durability, and performance your research alloy applications require. It empowers innovation across medical, robotic, and smart material research with reliability and repeatability.

Choose next-generation materials. Choose elite research-grade alloys. Contact us now to discuss your custom alloy needs and move your research forward.

•Mechanical properties

Upper platform |

Tensile |

Elongation |

Residual deformation |

Phase transition |

>350MPa |

>1000MPa |

>10% |

<0.5% |

-10~20℃ |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.