Description

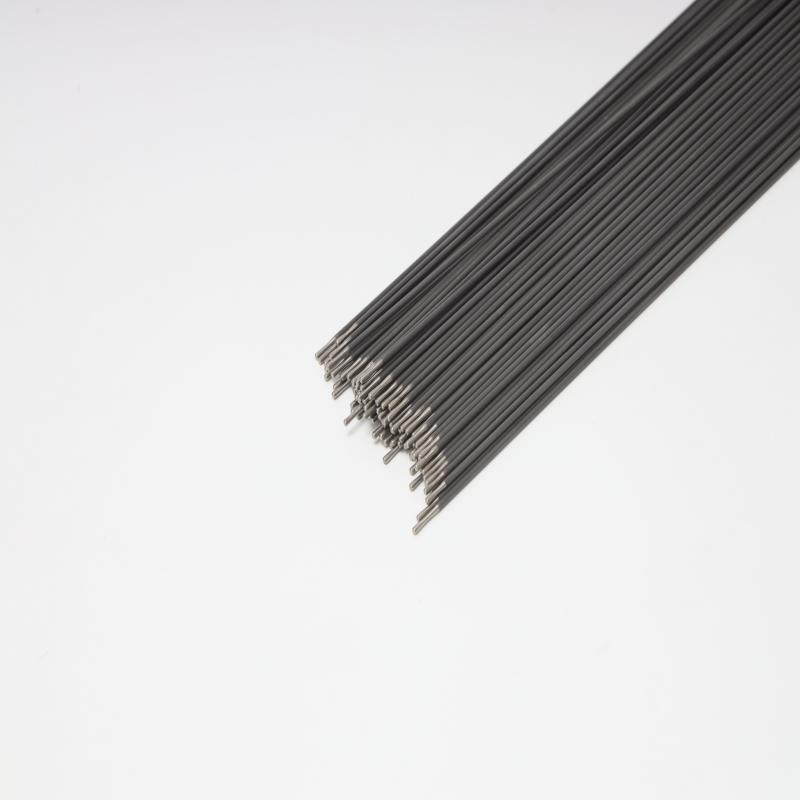

Shape Memory Alloys Welding Formed Parts: Durable Nickel Titanium Solutions

Unlock the exceptional capabilities of Shape Memory Alloys (SMAs) with our premium Nickel Titanium Welding Formed Parts. We expertly transform advanced Nitinol materials into complex, reliable components that deliver unmatched performance. Our parts remember their original shape, offer remarkable superelastic strength, resist corrosion in extreme environments, and provide exceptional longevity. Designed for the most demanding applications, our SMA parts ensure durable and precise solutions.

Superior Materials: Medical & Industrial Grade Superelastic Nitinol

Our primary material is top-tier superelastic Nitinol, including medical-grade and industrial-grade alloys such as SE508. This premium material offers extraordinary flexibility, enabling parts to bend, stretch, and spring back flawlessly under repeated stress without permanent deformation. Ideal for use inside the human body, it also exhibits excellent resistance to salty water and harsh chemicals. We source only the highest quality Nitinol wire and tubing, guaranteeing consistent and reliable performance in every part.

Versatile Sizes and Advanced Forming Techniques

Using state-of-the-art welding and forming processes, we handle a wide range of sizes—from ultra-fine 0.05 mm (0.002 inches) wires to robust 7.0 mm (0.275 inches) diameters, including thin-walled tubing. This versatility allows us to produce intricate medical device components, strong structural elements for aerospace and industrial uses, and more. Share your size and design needs with us — we tailor the perfect SMA solution.

Industry Applications: From Medical Devices to Aerospace

-

Medical Device Manufacturing: Complex catheter frameworks, stent connectors, guidewire tips, orthodontic wires, and bone fixation devices. Superelasticity and shape memory provide safe navigation, compact delivery, and secure deployment.

-

Aerospace & Defense: Vibration dampers, actuators, couplings, and adaptive release mechanisms withstand extreme environments with corrosion resistance and shock absorption.

-

Robotics & Automation: Flexible joints, micro-actuators, and sensors offering precise control, consistent force, and long-lasting fatigue resistance.

-

Oil & Gas Fluid Control: Durable downhole tools, valve components, and sensors designed for high pressure, bending stress, and aggressive chemical exposure.

-

Consumer Electronics: Tiny actuators, flexible connectors, and micro-switches enable smart, reliable device performance.

-

Advanced Research: Custom SMA actuators and prototypes supporting innovative smart structures and sensor technologies.

Why Choose Our Shape Memory Alloys Welding Parts?

-

Expertise in Shape Memory & Superelasticity: We deliver predictable shape recovery and flexible superelastic performance to solve complex engineering challenges.

-

Biocompatibility & Corrosion Resistance: Our parts meet ISO 10993 standards for medical safety and resist harsh industrial conditions.

-

Long Fatigue Life: Our Nitinol components withstand millions of stress cycles, outperforming traditional metals in durability.

-

Precision Laser Welding & Forming: Advanced techniques maintain Nitinol’s essential properties while creating strong, accurate joints.

-

Stringent Quality Control: Dimensional checks, mechanical testing, transformation temperature verification, and surface inspection ensure consistent, certified products.

-

Custom Design Power: Tell us your challenge. Our engineers partner with you. We tailor designs specifically for your application and Nitinol’s special behavior.

-

Deep Nitinol Know-How: We know SMA science inside out. Our deep metallurgical knowledge covers phase changes and how we make it. This ensures your parts work perfectly right from the start.

-

Proven Industry Reliability: Trusted by leading companies in critical applications requiring the highest standards.

Get precision-crafted Nitinol parts built tough. Experience the power of Shape Memory Alloy welding formed components designed for maximum strength, lasting durability, and exact precision. Let’s partner up. Use Nitinol’s superelastic magic to create reliable, next-level solutions. Ready to tackle your challenge? Talk to our team now about your project.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.