Description

0.18mm Black Oxidized SMA Wire – Bidirectional Drive Precision – High-Performance Bidirectional Drive Solution

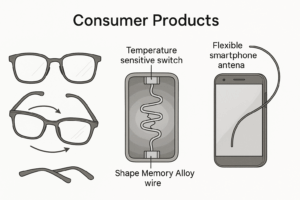

Discover unmatched reliability and precision control with our Black Oxidized SMA Wire, engineered specifically for bidirectional drive applications. With a fine 0.18mm diameter, this advanced Nitinol wire provides exceptional performance for medical and micro-mechanical systems requiring repeatable, responsive force in both directions.

Premium SMA Wire Materials

-

Core Composition: Crafted from high-purity Nickel Titanium alloy (Nitinol), this Shape Memory Alloy (SMA) ensures superior elasticity and shape memory functionality.

-

Precision Alloying: Our proprietary composition guarantees dependable superelasticity and thermal responsiveness for consistent wire behavior.

-

Medical-Grade Sourcing: Materials meet strict biocompatibility and traceability standards, essential for critical healthcare devices.

Advanced Black Oxide Surface Technology

-

Controlled Oxidation: The black oxide layer is formed through a proprietary thermal process, creating a uniform, matte black surface.

-

Low Friction: This finish dramatically reduces drag within catheters and delivery systems, improving maneuverability and tactile feedback.

-

Corrosion & Glare Resistance: Designed to resist bodily fluids and sterilization cycles, while minimizing visual interference during procedures.

-

Strong Bonding: The oxide layer adheres seamlessly to the Nitinol base, preventing flaking during aggressive use or flexing.

Exact Diameter for Critical Applications

-

Tight Tolerance Manufacturing: Our 0.18mm SMA wire maintains consistent diameter along the full spool length.

-

Ultra-Fine Navigation: Ideal for use in intricate pathways and micro components in neurovascular and ophthalmic devices.

-

Standard & Custom Lengths: Available in standard spool formats, with custom lengths upon request.

Ideal for Precision Medical Devices

-

Steerable Catheters & Guidewires: Enables bidirectional control for accurate tip movement through complex anatomy.

-

Minimally Invasive Surgical Tools: Powers actuation in laparoscopic instruments with smooth, responsive force.

-

Micro Actuators & Robotics: Offers high-resolution movement for compact, sensitive mechanisms.

-

Endoscopic & Vascular Devices: Supports precise positioning within small, tortuous spaces.

Why Choose Our 0.18mm SMA Wire

-

True Bidirectional Force: Performs equally well under push and pull loading conditions.

-

Exceptional Superelasticity: Withstands deformation and returns to form, ensuring resilience through repeated cycles.

-

Durable Black Finish: Increases wire lifespan and reliability in sterilized environments.

-

Precision Fabrication: Consistent performance spool-to-spool with minimized integration variation.

-

Trusted Manufacturing: Backed by comprehensive quality checks and expert SMA engineering support.

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.