Description

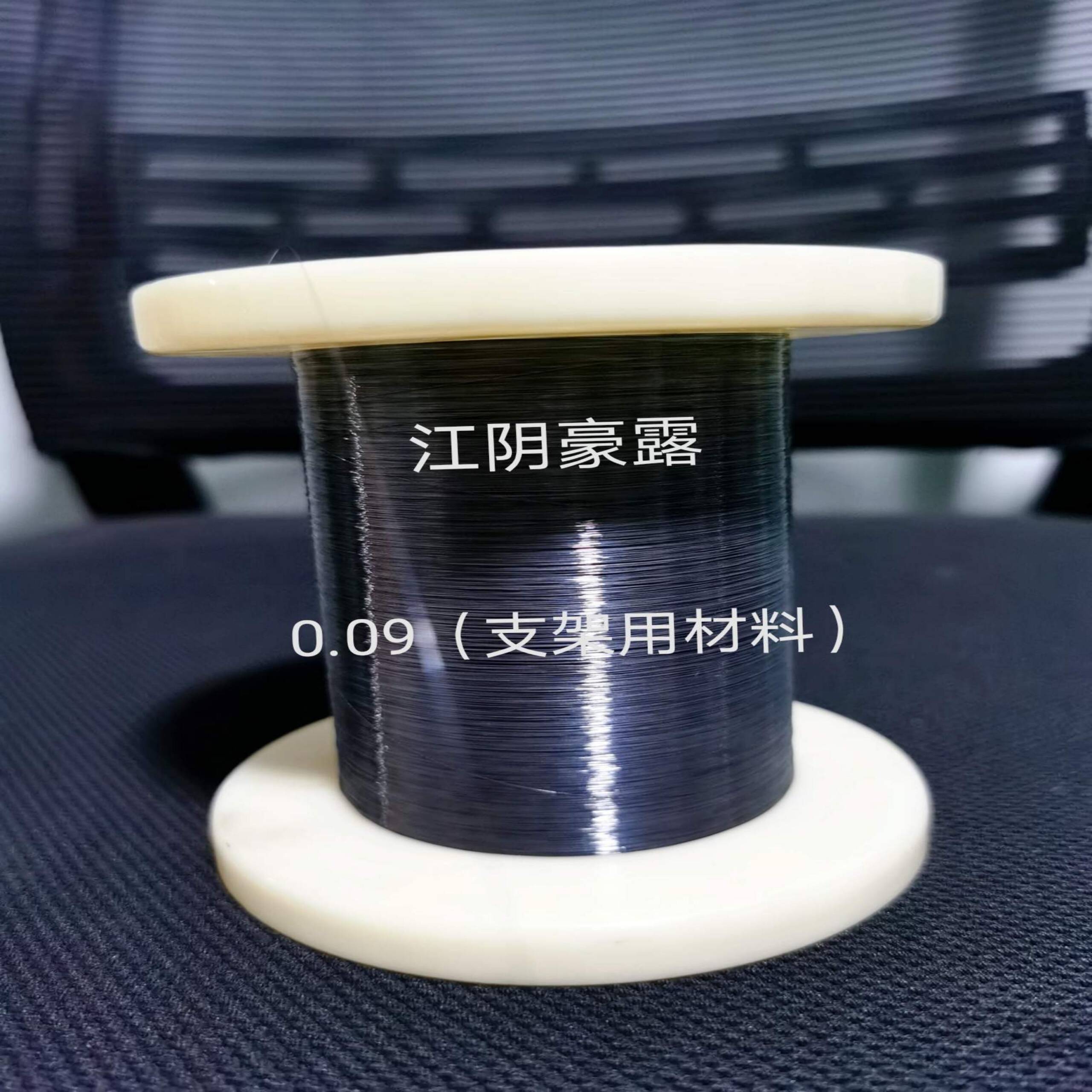

Specialty Alloys: Ultra-Fine Black Oxidized Nitinol Wire 0.09mm for Precision Applications

Unlock the power of specialty alloys with our Black Oxidized Nitinol Wire, precisely crafted to an ultra-fine 0.09mm diameter. This advanced wire combines the unique properties of nickel-titanium, a renowned specialty alloy, with a durable black oxide finish, offering an exceptional solution for demanding medical, electronic, and micro-scale engineering applications.

Material Excellence in Specialty Alloys

Our core material is high-purity Nickel-Titanium (Nitinol), a versatile specialty alloy known for its remarkable shape memory effect and superelasticity. We ensure strict composition control and source only the finest nickel and titanium, guaranteeing consistent, predictable behavior critical for high-performance uses.

Black Oxide Finish Enhancing Specialty Alloy Performance

The uniform black oxide coating on this nitinol wire creates a dense, adherent surface layer that enhances visibility, reduces friction, and maintains excellent biocompatibility. This surface treatment elevates the functional value of the specialty alloy, especially in applications requiring smooth operation and clear imaging contrast.

Precision 0.09mm Diameter – Specialty Alloy Micro Wire

Manufactured with extreme precision, the 0.09mm diameter highlights our advanced capability in producing miniature specialty alloys wire. This dimension allows access to narrow spaces and intricate assemblies, essential for minimally invasive medical devices and micro-mechanical systems. Consistent diameter control ensures reliable mechanical and superelastic performance across the entire length.

Applications of Specialty Alloys in Medical and Micro-Engineering Fields

This black oxidized nitinol wire serves a broad range of industries:

-

Medical Devices: Ideal for micro-stents, guidewires, micro-catheters, and surgical tools used in cardiovascular, neurovascular, and ophthalmic procedures.

-

Electronics & Sensors: Used in micro-actuators, vibration damping, and miniature sensor components requiring precision movement.

-

Micro-Robotics & Mechanics: Perfect for robotic joints, micro-grippers, and silent actuation systems.

-

Jewelry & Wearable Tech: Valued for its flexibility and unique black finish in eyeglass frames and high-end jewelry.

Why Choose Our Specialty Alloys Black Oxidized Nitinol Wire

-

Unmatched precision with consistent 0.09mm diameter control

-

Superior black oxide finish for reduced friction and enhanced visibility

-

Certified biocompatibility for medical and implantable use

-

Customizable transformation temperatures and mechanical properties

-

Maintains superior fatigue life and elastic recovery even at extremely small diameters.

Experience the precision and versatility of specialty alloys in an ultra-fine nitinol wire engineered for your most demanding micro-scale applications. Contact us today to elevate your next innovation with our Black Oxidized Nitinol Wire 0.09mm.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.