Description

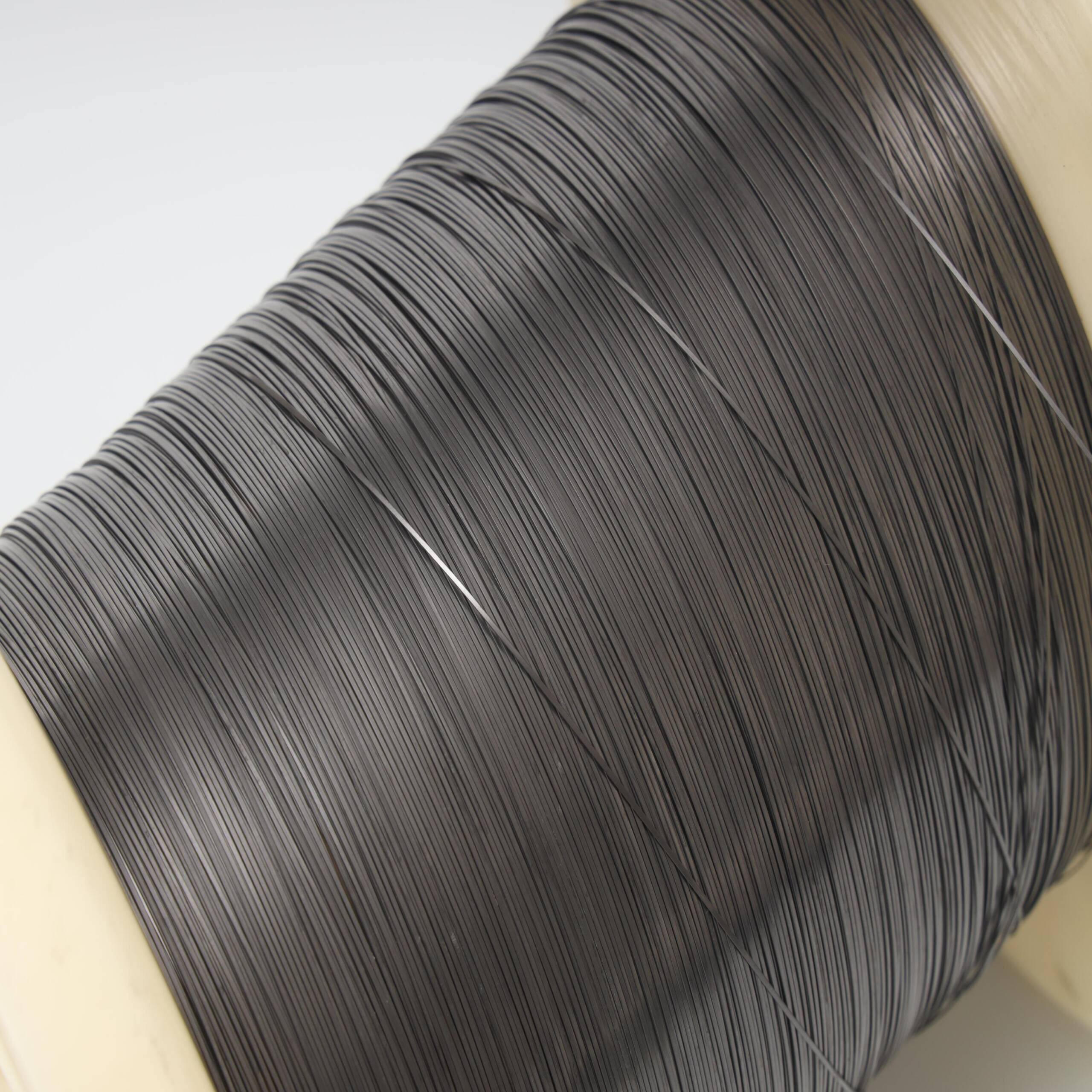

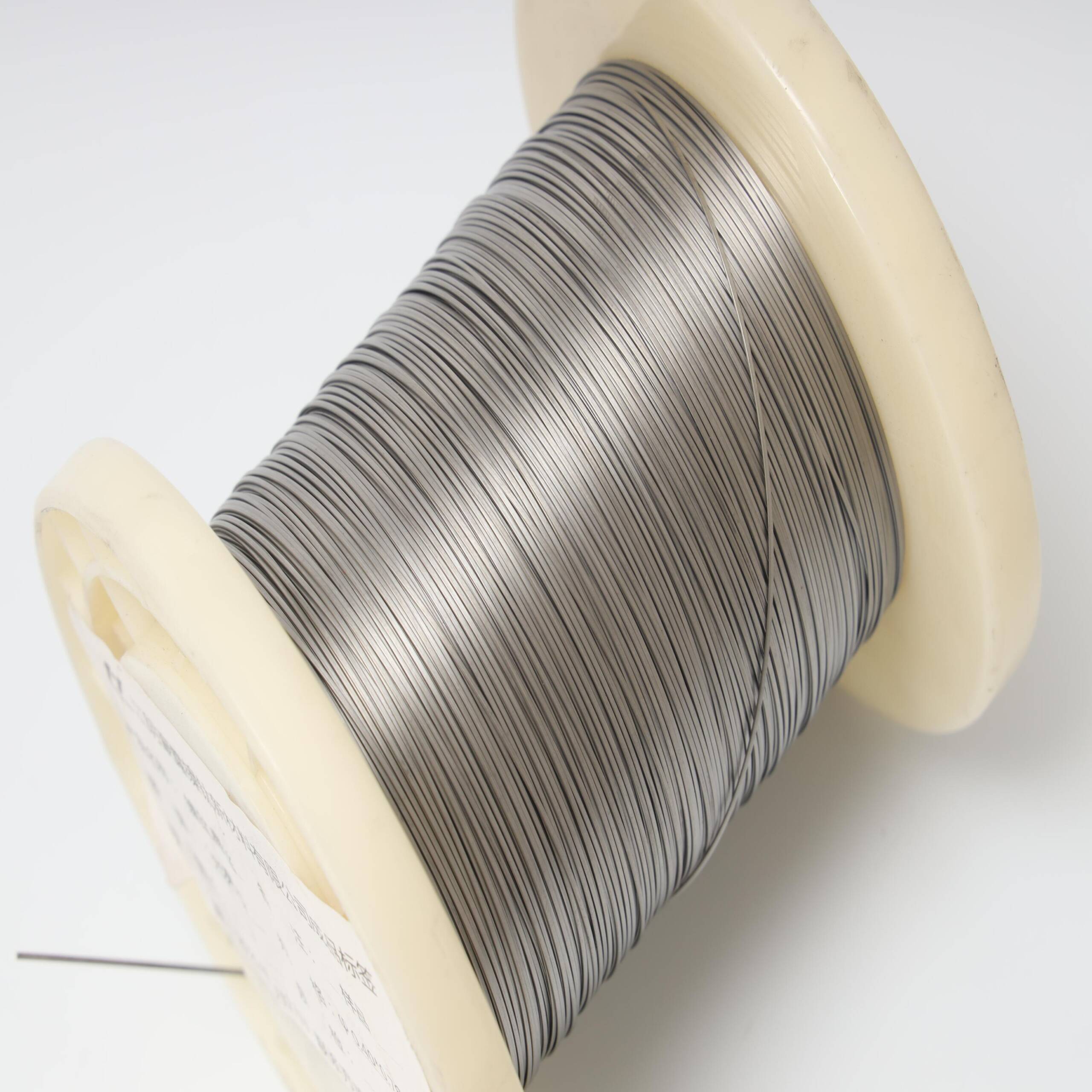

Nitinol Flat Wire: Smart Alloy for Medical, Aerospace & Robotics

What Is Nitinol Flat Wire?

Nitinol flat wire is a precision-engineered form of nickel-titanium (NiTi) alloy that combines the extraordinary thermomechanical properties of Nitinol with the geometric advantages of a flat, ribbon-like profile. From the outset, it offers two key advantages: the shape memory effect (SME) and superelasticity, allowing it to return to a preset shape when heated or recover instantly from significant deformation.

Unlike conventional metals, this material enables high-performance solutions across industries where flexibility, strength, and accuracy are non-negotiable.

Exceptional Material Properties

One reason why Nitinol flat wire excels is due to its two core behaviors:

-

Shape Memory Effect: When exposed to temperatures above its transformation range (-15°C to 150°C / 5°F to 302°F), the wire returns to its original, programmed shape—even after being bent or twisted.

-

Superelasticity: At temperatures slightly above the Af point, it undergoes extensive strain—up to 10–30 times more than standard metals—and springs back to its original form upon unloading, without the need for heat.

In addition, it offers:

-

High fatigue life (>10⁷ cycles)

-

Excellent corrosion resistance

-

Proven biocompatibility for long-term use in medical and biological environments

Real-World Applications Across Industries

Thanks to its versatile profile and smart properties, Nitinol flat wire is revolutionizing design across sectors:

-

Medical Devices: Orthodontic archwires, vascular stents, and tools for minimally invasive procedures

-

Consumer Electronics: Bluetooth earhooks, flexible antennas, and smart actuators in wearables

-

Robotics & Aerospace: Lightweight actuators, vibration-damping mechanisms, and adaptive structural components

-

Industrial Systems: Seismic dampers, micro-switches, and motion-control sensors

Notably, its use extends to flexible eyeglass frames and children’s toys, showcasing a rare blend of strength, safety, and resilience.

Specifications and Core Advantages

Material Composition: 54.5–57% nickel, with titanium making up the balance

Surface Options: Polished, burr-free, or cleaned for medical compatibility

Operating Range: Stable and functional between -15°C to 150°C

Key Performance Benefits:

-

Consistent elastic behavior

-

Strong resistance to fatigue, oxidation, and corrosion

-

Reliable performance in cyclic or repetitive-motion systems

-

Better nesting efficiency than round wires, reducing manufacturing waste

Seamless Manufacturing Integration

To further enhance usability, Nitinol flat wire is compatible with various advanced fabrication methods, including:

-

Laser cutting

-

Photo etching

-

Precision forming

Its flat geometry allows engineers to achieve complex designs that are not feasible with traditional round wire. Moreover, it supports tighter packaging, which reduces cost and material usage in sheet-based production environments.

Frequently Asked Questions

Q1: How does flat wire differ from standard Nitinol wire?

Flat wire offers increased surface contact for sensors and actuators, while retaining the same shape memory and superelastic behaviors.

Q2: Is customization available?

Absolutely. Properties such as transformation temperature, surface finish, and tensile strength (ranging from 70–690 MPa) can be tailored to meet specific needs.

Q3: Why is flat wire ideal for medical use?

Because it’s biocompatible, corrosion-resistant, and highly durable, making it suitable for implants and instruments that endure repeated stress inside the human body.

Conclusion

In conclusion, Nitinol flat wire is not just a material—it’s an enabler of innovation. Combining the intelligence of shape memory alloys with the form factor needed for modern applications, it delivers unmatched performance in medicine, aerospace, robotics, and beyond. By incorporating this smart alloy into your designs, you open the door to efficient, resilient, and forward-thinking solutions.

Reviews

There are no reviews yet.