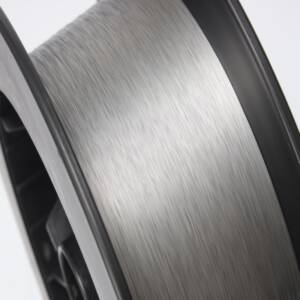

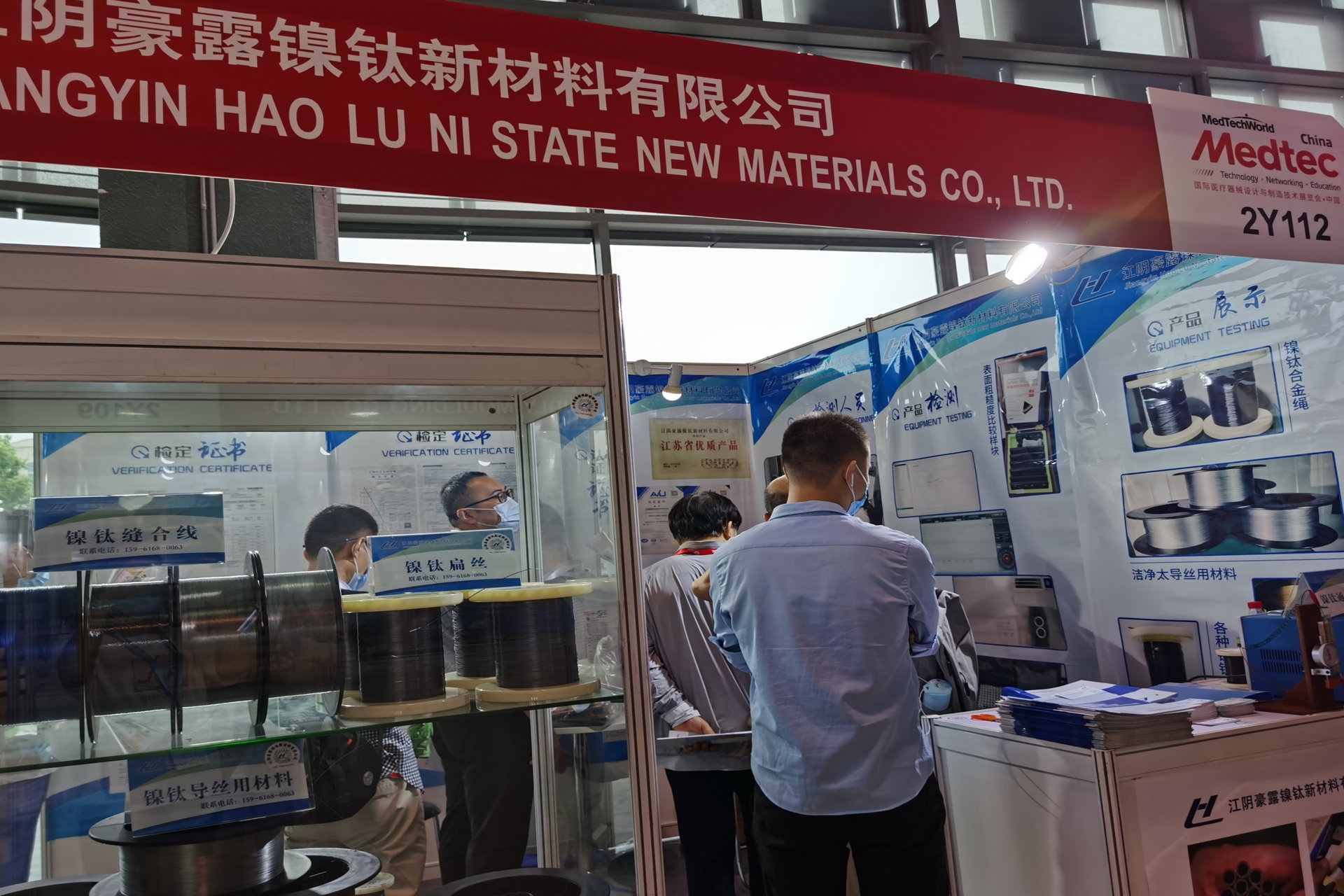

NI TI.

MEDICAL MATERIALS

Committed to the development and production of nickel-titanium memory alloy materials and nickel-titanium alloy products for medical use

Integrity Wins the world

Limited life Unlimited pursuit

Profession focus and innovation

Dedicating for human

healthcare

Quality Assurance

Get Your Instant

Quote Now

Multiple experts, ringtone customization.

Customized production of relevant production equipment according to customer requirements, can provide customers with a complete drawing process.

Magnesium alloy

medical material

As a biodegradable medical material, medical magnesium alloy is known as the third generation of biomedical materials.

Medical magnesium alloy also has a controllable corrosion rate, which has a good application prospect in cardiovascular implantation and bone repair.

Hot Sales

Listen to what they say

“The nickel-titanium alloy wire we received has been a game-changer for our manufacturing process. Not only did it arrive with flawless surface finish and zero defects, but its mechanical properties also remained stable through multiple production cycles. Our quality control team confirmed near-perfect compliance with ASTM F2063 specifications. The combination of your material’s reliability and your responsive customer service has streamlined our operations and reduced downtime. Highly recommended for mission-critical applications!”

Dan

“We are thoroughly impressed with the exceptional quality of your nickel-titanium alloy wire. Its consistent superelastic properties and precise dimensional tolerances have significantly improved the performance of our medical device prototypes. After rigorous testing, the wire demonstrated remarkable fatigue resistance and shape memory retention, exceeding our industry standards. Your team’s commitment to material excellence and technical support has made you an indispensable partner for our R&D projects. We look forward to expanding our collaboration!”

Frank

Consectetur adipiscing

Panel Cleaning

Consectetur adipiscing

Maintenance

Consectetur adipiscing

Calibration

Performance, Quality and Reliability

How Does Green Power Work?

Can your Nitinol springs withstand extreme temperature fluctuations during space missions?

Yes. Our aerospace-grade Nitinol springs are engineered with a **transformation temperature range of -100°C to +150°C**, ensuring stable superelasticity in both cryogenic and high-heat environments. The alloy composition (Ni: 50.6 at%) is optimized for minimal hysteresis loss, validated through 500+ thermal cycling tests under simulated orbital conditions. These springs meet NASA’s outgassing standards (ASTM E595) and retain 98% shape recovery after prolonged stress.

How durable are Nitinol hinges for foldable phones after repeated bending?

Our hinges endure **>500,000 folding cycles** without fatigue failure, thanks to Nitinol’s intrinsic 8% recoverable strain limit. A proprietary thin-film coating (DLC – Diamond-Like Carbon) reduces friction by 40% while maintaining a sleek profile. Rigorous testing confirms zero plastic deformation even at -20°C, making them ideal for extreme climates. Each batch complies with MIL-STD-810G durability benchmarks.

Do your Nitinol downhole tools resist hydrogen embrittlement in high-pressure sour wells?

Absolutely. Our components undergo a specialized **hydrogen barrier treatment** during manufacturing, reducing hydrogen absorption by 90% compared to untreated Nitinol. Tested in H₂S-saturated environments (per NACE MR0175), they maintain fracture toughness above 80 MPa√m at 10,000 psi. The alloy’s corrosion rate is <0.001 mm/year in pH 3–12 conditions, ensuring 15+ years of service life in aggressive formations.