Description

Nitinol Braid for Medical Devices: Superelastic Precision You Can Trust

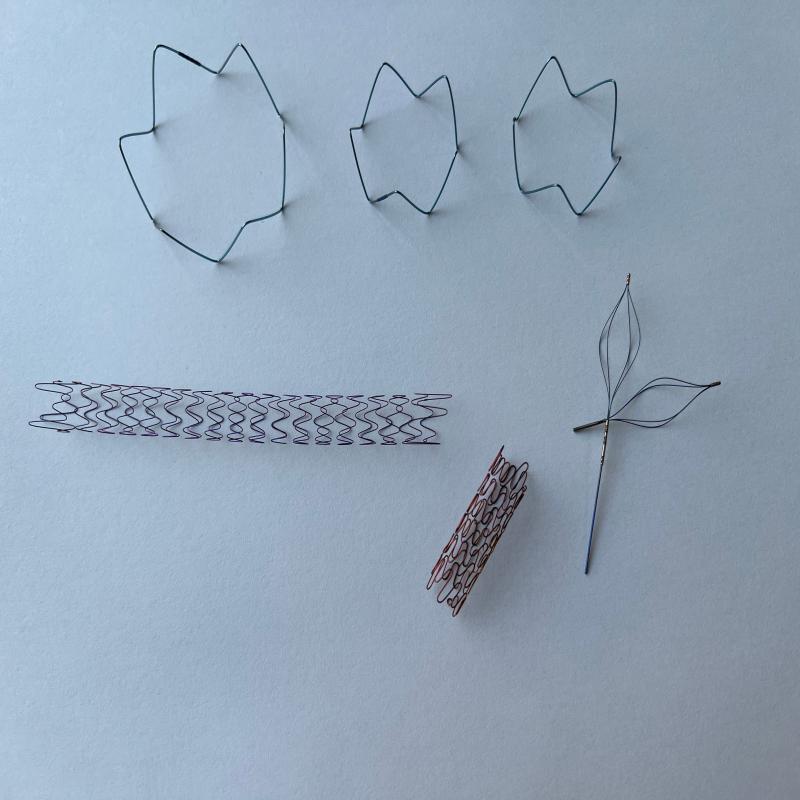

Nitinol braid is a transformative technology driving the next generation of medical devices. Crafted from high-quality medical-grade nickel titanium, our nitinol braid delivers exceptional flexibility, proven biocompatibility, and robust structural performance.It’s the ideal solution for minimally invasive procedures, advanced implant delivery, and vascular navigation.

Medical-Grade Nitinol Braid for Consistent Quality

Certified, high-purity nickel titanium wire forms the basis of every nitinol braid we produce.This biocompatible material resists corrosion and maintains strength in dynamic, physiological environments. Sourced from trusted suppliers, each spool supports traceability and meets ISO and ASTM medical standards.

Superelasticity in Every Strand

Superelastic behavior defines the performance of our nitinol braid. It returns to its original shape after large deformations—crucial for guidewires, microcatheters, and stent systems. As a result, the device maintains excellent navigation performance, resists kinking, and reliably returns to its original shape at physiological temperatures.

Custom Diameters and Pitch Control

We offer a wide range of nitinol braid sizes, from ultra-fine diameters to robust structural braids. Customize wire count, pitch, and coverage to meet your device’s needs. Dimensional consistency ensures reliable integration into your product assemblies.

Optimized for a Range of Medical Applications

Nitinol braid enables advanced solutions in a wide range of interventional and surgical applications:

-

Vascular Access: Smooth navigation and torque response in guidewires and embolic protection systems

-

Stent Delivery Systems: Stable yet flexible braiding ensures precise deployment

-

Neurovascular Devices: Extreme flexibility for safe access to cerebral anatomy

-

EP Catheters: Structural support and electrode alignment for mapping and ablation

-

Endoscopy Tools: Navigate complex GI and pulmonary anatomy effortlessly

-

Orthopedic Implants: Strong fatigue-resistant braid for trauma fixation

-

Occlusion Devices: Mesh structures for vascular plugs and septal occluders

-

Implant Delivery Shafts: Flexibility and stability during deployment

Why Choose Our Nitinol Braid?

-

Proven Biocompatibility: Certified to ISO 10993 standards

-

Reliable Superelastic Performance: ASTM F2063 compliant nitinol

-

Precision Control: Tight tolerances in diameter and pitch

-

Surface Options: Oxide, etched, or polished finishes for low thrombogenicity

-

Durability: Excellent fatigue resistance for cyclic loading environments

-

Manufactured under ISO 13485 standards with comprehensive quality assurance and rigorous testing.

-

Customization: Engineering support for diameter, wire count, and finish

-

Stable Supply: Reliable sourcing and fast turnaround

Partner in Innovation

Our nitinol braid is more than a material—it’s a medical enabler. With decades of experience in nitinol processing and device integration, we provide unmatched expertise, precision manufacturing, and support.

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.