Description

Ultra-Fine 0.045mm Medical Grade Nitinol Wire: Precision for Advanced Devices

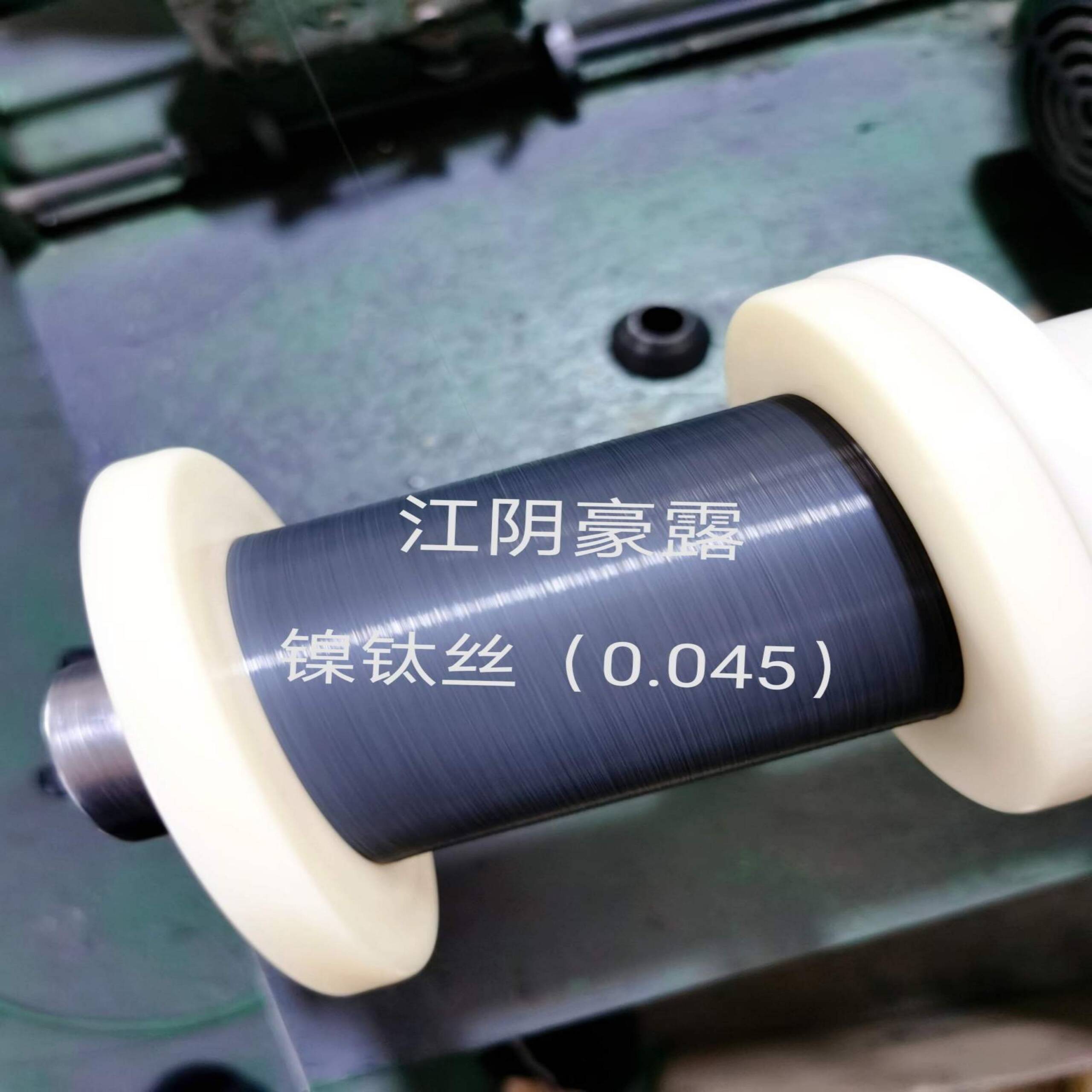

Unlock new levels of medical innovation with our ultra-fine medical grade nitinol wire, measuring just 0.045mm in diameter. Designed to meet the rigorous standards of ASTM F2063, this premium wire is ideal for implantable devices requiring excellent flexibility, fatigue resistance, and biocompatibility.

Superelastic Power in a Micro Scale

Crafted from top-tier superelastic Nitinol, this wire features remarkable shape memory and elasticity. It returns to its original shape even after extreme deformation—making it ideal for demanding medical applications. The wire’s superelastic behavior ensures smooth, damage-free performance during complex procedures.

Superior Flexibility and Kink Resistance

We specialize in superelastic grades engineered for medical use. These wires deliver consistent flexibility and kink resistance inside the human body. Triggered by temperature changes, their shape memory effect allows for predictable, repeatable results in real-world conditions.

Why Choose 0.045mm Diameter?

Thinner than a human hair, this 0.045mm wire offers exceptional maneuverability and precision. It’s perfect for intricate devices where control and consistency are critical. Our advanced process ensures tight dimensional tolerance and uniform mechanical properties across every spool.

Key Applications of Medical Grade Nitinol Wire

-

Guidewires: Navigate complex vasculature with ease and flexibility.

-

Micro Catheters: Build precision delivery systems for targeted therapy.

-

Orthodontic Archwires: Deliver gentle, controlled forces for patient comfort.

-

Minimally Invasive Tools: Enable smaller, smarter surgical instruments.

-

Endoscopic Devices: Improve articulation and visibility in tight anatomical spaces.

-

Stent Delivery Systems: Ensure smooth, accurate stent deployment.

-

Neurovascular Devices: Operate with confidence in sensitive brain vasculature.

-

Ophthalmic Tools: Build flexible instruments for delicate eye procedures.

Product Highlights: What You Can Expect

-

Performance: High fatigue resistance and reliable superelastic strain recovery.

-

Surface Finish: Smooth, low-friction surface—electropolished options available.

-

Consistency: Batch-to-batch reliability ensures trusted results.

-

Formability: Easily shaped into custom geometries and set with heat treatment.

-

Biocompatibility: Fully compliant with ISO 10993 standards for implants.

-

Precision Handling: Requires proper coiling tools to avoid kinks or deformation.

-

Traceability: Full certification and quality control documentation provided.

Partner with a Trusted Nitinol Supplier

When performance and safety matter, choose a reliable manufacturer of medical grade nitinol wire. Our ultra-fine 0.045mm solution empowers groundbreaking medical innovations—from microsurgery to neurovascular navigation. Trust our material expertise to help bring your next-generation device to life.

•Diameter & Tolerance

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

Diameter(mm) |

Tolerance(mm) |

4.000-2.000 |

±0.025 |

0.350-0.260 |

±0.010 |

0.08-0.050 |

±0.005 |

2.000-1.000 |

±0.020 |

0.260-0.150 |

±0.007 |

0.050-0.025 |

±0.005 |

1.000-0.350 |

±0.010 |

0.150-0.080 |

±0.005 |

0.025-0.018 |

±0.003 |

•Mechanical properties

Max force(N) |

Tensile(MPa) |

Elongation % |

Upper stress(MPa) |

Residual strain(WT%) |

At temp |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 55.96 |

(10±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 56.1 |

(-30±10) |

Base on diam |

≥1000 (1350) |

≥10 (15) |

≥400 (460) |

<0.5 50.0 |

(60±10) |

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Reviews

There are no reviews yet.